How AI-Powered Solutions Transform Delivery Inventory Management in Kitchen Cabinet Manufacturing?

5 min read

5 min read

Kitchen cabinets sitting in warehouses are basically expensive wooden zombies. They eat up space, devour working capital, and occasionally disappear into the void of mismanaged inventory. Welcome to the wild world of kitchen cabinet supply chain management, where a single delayed delivery can turn a happy homeowner into your worst Yelp nightmare.

Here’s a sobering thought: global supply chain disruptions in 2024 led companies to incur financial losses averaging 8% of their annual revenue—a hit that could sink smaller operations if it continues (source). This isn’t pocket change; it’s a real danger to your bottom line and survival in a competitive market. The real kick in the teeth? Most delays happen after the cabinets are perfectly crafted and ready to ship.

They’re the difference between thriving and becoming another cautionary tale at industry conferences. Time to stop treating inventory like a guessing game and start treating it like the science it should be.

Kitchen cabinet suppliers face a growing mix of logistical, inventory, and communication hurdles that disrupt delivery performance and strain distributor expectations.

Playing whack-a-mole with delivery problems beats actually preventing them, apparently. Most manufacturers react to disasters rather than seeing them coming, like driving while staring into the rearview mirror.

Without real-time visibility into what distributors actually need versus what they say they need, warehouses become expensive cabinet graveyards where perfectly good inventory goes to die while customers scream bloody murder about delays.

Nothing says “professional partnership” quite like having 500 units of the wrong cabinet style while your distributor begs for the 50 units you don’t have. This inventory Russian roulette destroys order fulfillment rates faster than a server crash on Black Friday.

Trust evaporates when contractors show up to empty shelves or worse, discover their storage space buried under unwanted oak monstrosities nobody ordered, turning reliable partners into bitter enemies plotting their vendor switch.

Are you tired of watching perfectly good inventory collect dust while urgent orders go unfulfilled? It’s time to stop the chaos before it destroys another distributor relationship.

Manufacturers using AI-driven inventory optimization reduce inventory carrying costs, improve order accuracy, and achieve faster returns on investment. If delivery delays are impacting revenue, reputation, and repeat business, it’s time to act

Flying blind through kitchen cabinet supply chain management works about as well as coding without a monitor. Communication between manufacturers and suppliers becomes a tragic game of telephone where “slight delay” translates to “complete disaster” three emails later.

By the time anyone realizes there’s a problem worth solving, it’s already cascaded through the supply chain like malware through an unpatched network, contaminating everything from production schedules to customer satisfaction scores. But here’s what executives really want to know: “What’s the actual ROI timeline for implementing these AI systems?”

The answer isn’t as painful as you’d think – most manufacturers see measurable improvements within 60-90 days, with full ROI typically achieved within 12-18 months, assuming you don’t sabotage the implementation by committee.

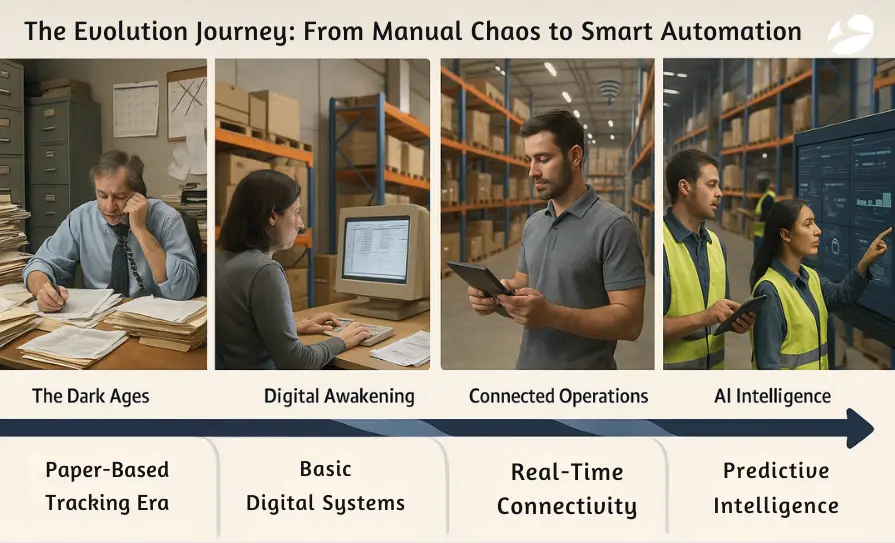

AI-powered tools are reshaping how manufacturers predict demand, track deliveries, and manage inventory. These capabilities make delivery operations far more accurate and efficient than traditional methods.

Trying to predict delivery needs without data analytics is like playing Minesweeper on expert mode while drunk and blindfolded. AI-driven inventory optimization digs through historical order patterns and seasonal trends, spotting patterns humans miss faster than a speed-runner finding game exploits.

Focus on capturing delivery timestamps, order volumes, and seasonal patterns first – these three data points alone drive 70% of prediction accuracy.

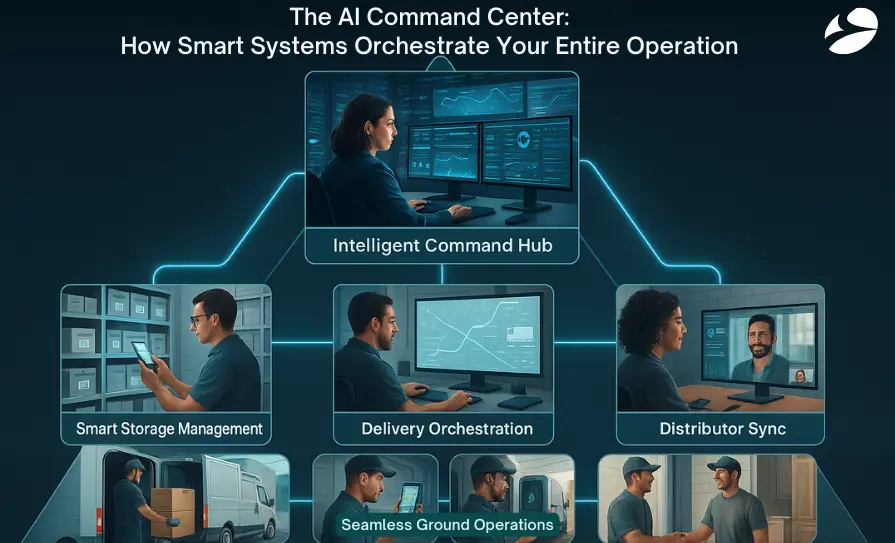

Watching deliveries without real-time tracking feels like monitoring server uptime through prayer and occasional phone calls from angry users. Integration with logistics systems provides live updates that make GPS stalking look amateur, catching problems before they snowball into full-blown disasters.

BiztechCS can develop integrated tracking dashboards that provide complete visibility across your entire delivery network, because knowing where your cabinets are beats explaining to contractors why their kitchen install just became a Netflix documentary about patience.

Manual inventory tracking works about as effectively as managing datacenter cooling with a desk fan and good intentions. Automated systems track finished goods through warehouses while dynamically adjusting AI delivery scheduling based on actual demand, not Bob’s sticky note system that died with Windows XP.

The elimination of manual process errors alone saves more money than switching your entire office from premium to regular coffee, plus nobody has to decode Bob’s hieroglyphic handwriting anymore.

Leadership teams often ask, “How much training will our warehouse staff need to operate these AI systems?”

Surprisingly little – modern AI interfaces are designed for humans who panic at Excel macros, requiring about 2-3 days of hands-on training before your team operates them better than they operate their smartphones.

Sending the same delivery schedule to every distributor is like giving everyone admin access and hoping for the best. BiztechCS can create AI algorithms that learn and adapt to each partner’s unique requirements and preferences, optimizing shipment sizes and frequencies better than any spreadsheet warrior ever could.

This AI-powered inventory management transforms contractor relationships from toxic Reddit threads into actual partnerships where people get their damn cabinets when promised, revolutionary concept though it may be.

BiztechCS brings a blend of industry insight, tailored technology, and scalable AI solutions that directly address the operational challenges manufacturers face today.

Kitchen cabinet production cycles follow logic that makes quantum physics look straightforward, with lead times that shift like server loads during a DDoS attack. BiztechCS can navigate these production nightmares because we’ve lived through enough of them to write horror novels about distributor meltdowns and contractor rage-quits.

The gap between industry experts and generic consultants is like comparing someone who actually plays Dark Souls to someone who once watched a YouTube tutorial.

Forcing your unique manufacturing process into generic software is like running AAA games on integrated graphics and wondering why everything’s on fire. BiztechCS can design solutions that integrate with existing manufacturing processes, rather than demanding you torch everything and start over like some software tyrant.

We can align perfectly with your current workflow because burning money on complete system overhauls is about as smart as mining Bitcoin on your production servers. BiztechCS can develop tailored implementations for kitchen cabinet supply chain management that scale with your growth rather than becoming digital cement blocks tied to your ankles.

Wondering if your unique manufacturing process can actually benefit from AI without a complete system overhaul? Your operation deserves solutions built for your specific challenges, not generic software that forces you to adapt.

Manufacturers using AI-driven inventory optimization reduce inventory carrying costs, improve order accuracy, and achieve faster returns on investment. If delivery delays are impacting revenue, reputation, and repeat business, it’s time to act

One-size-fits-all approaches work about as well as one-size-fits-all pants, which is to say they make everyone miserable and fit nobody properly. We create customized solutions that actually fit your business, rather than making your business contort itself to fit the software. The C-suite inevitably wonders, “What happens if our business model changes or we acquire another manufacturer?”

Building systems without scalability is like provisioning servers for the current load and praying traffic never increases, a strategy that ends in tears and emergency meetings. BiztechCS can implement cloud-native architecture and microservices that handle growth spurts better than your teenage nephew handles pizza at family dinners. We can build systems flexible enough for single-site operations today and multi-site empires tomorrow without requiring complete architectural rebuilds every expansion phase.

BiztechCS can create predictive logistics for manufacturers that grow alongside your business expansion, rather than becoming another legacy system everyone’s afraid to touch. Our AI-powered inventory management solutions don’t just work for your current size; they’re built to handle whatever insanity your growth throws at them.

Think of it as future-proofing that actually works, unlike that “future-proof” gaming rig you built in 2015 that now struggles with browser tabs.

Several advanced technologies power modern delivery optimization, each playing a distinct role in improving accuracy, visibility, and operational efficiency.

Continuous improvement means AI-driven inventory optimization evolves with your business, unlike your coworker Dave, who’s been making the same errors since Windows Vista was considered cutting-edge.

IoT sensors turn your warehouse into a surveillance state that actually serves a purpose, tracking every cabinet’s location and status like an overly attached girlfriend monitoring your Discord status.

These little digital snitches send automated alerts before disasters strike, catching problems faster than antivirus software catches sketchy downloads from questionable torrenting sites. Integration with existing warehouse management systems means real-time visibility without rebuilding everything from scratch, because nobody has time for another migration project that’ll haunt their weekends. Management always asks the uncomfortable question: “What’s our contingency if the AI system fails?”

Smart implementations include fallback protocols and manual override options that kick in faster than your disaster recovery plan, ensuring operations continue even if the AI decides to take a sick day. Though honestly, it’s more reliable than most human employees.

Cloud computing makes AI-powered inventory management accessible from anywhere, turning delivery optimization into something you can handle from your phone while pretending to pay attention in meetings.

Real-time data sharing across teams beats the old method of Excel sheets passed around like forbidden scrolls, eliminating version control nightmares that make Git merge conflicts look pleasant.

The right time to adopt AI-powered inventory management is when customer complaints about delivery times start outnumbering positive reviews, and your distribution network looks like spaghetti code written by an intern on Red Bull.

Missing contractor deadlines becomes your company’s signature move while your team plays whack-a-mole with scheduling disasters that multiply faster than browser tabs during a debugging session. BiztechCS can create customized implementation roadmaps that align with your operational calendar, using a phased approach that won’t torch your operations like a failed production deployment on Friday afternoon.

Smaller manufacturers can get AI delivery scheduling running in weeks, not months, while larger operations need more time but avoid the nuclear meltdown of doing everything at once.

The implementation timeline depends on your business size, but waiting until the ship is entirely underwater before starting to bail is about as smart as using “password123” for your root access. Senior leadership often hesitates, asking, “Can we pilot this in one facility before full rollout?”

Absolutely – BiztechCS recommends starting with a single distribution center or product line, proving the concept works before betting the entire farm, because nobody wants to be the executive who approved the project that became a Harvard Business School case study in failure.

Stop treating predictive logistics for manufacturers like optional DLC when it’s actually the patch that fixes your broken game.

AI-powered inventory management isn’t some Silicon Valley fever dream; it’s the difference between running a profitable operation and becoming a cautionary tale at trade shows where vendors whisper about your spectacular failure.

Reduced delays, improved inventory turnover, and distributor relationships that don’t resemble toxic gaming lobbies are just the baseline benefits of ditching Stone Age logistics for AI delivery scheduling. Business owners consistently ask, “How do we measure success beyond just delivery times?”

The metrics that matter include inventory carrying cost reduction (typically 20-30%), order accuracy improvement (jumping from 85% to 98%+), and distributor satisfaction scores that actually move upward instead of circling the drain – all trackable through the same AI platform that’s fixing your problems.

Kitchen cabinet supply chain management without AI is like trying to win a boss fight with starter equipment while everyone else has endgame gear. The choice is simple: adopt AI-driven inventory optimization now or spend the next decade explaining to angry contractors why their cabinets are playing hide-and-seek in your warehouse.

Ready to transform your delivery chaos into predictable, profitable operations? Stop letting inventory management be the bottleneck that’s strangling your growth potential.

Artificial Intelligence (AI)

161

By Nandeep Barochiya

Odoo

245

By Uttam Jain

Artificial Intelligence (AI)

463

By Nandeep Barochiya