https://www.biztechcs.com/blog/what-if-your-fleet-could-predict-breakdowns-before-they-happen/

Your fleet vehicles are like teenagers with car keys. They’ll break down at the worst possible moment, cost you a fortune, and never tell you what’s wrong until it’s too late. Fleet maintenance optimization used to mean crossing your fingers and hoping that the weird noise wasn’t expensive.

Now we have something better than prayer and duct tape. Predictive-maintenance solutions are driving tangible results: research shows that firms using data-driven maintenance can reduce unplanned downtime by up to 50% (source).

That makes sense — because nobody enjoys explaining to clients why their delivery is stuck on the highway with a blown transmission. Enter AI predictive maintenance, the crystal ball your maintenance team never knew they needed. Backed by an experienced AI Development Company, this technology transforms vehicle health monitoring from reactive panic to proactive planning—detecting issues before they escalate into costly breakdowns and missed commitments.

Think of it as having a psychic mechanic who knows your truck needs new brake pads before the driver discovers this fact while barreling down a mountain pass. IoT-powered fleet management systems catch problems before they become screams, not after. The payoff hits harder than your morning espresso.

Companies using predictive-maintenance solutions for fleets report up to 35% fewer breakdowns and maintenance costs cut by around 32% (source). But executives often ask: “How quickly can we expect to see these results after implementation?” The answer varies, but most fleets start seeing measurable improvements within 3-6 months, with full ROI typically achieved within the first year.

Your vehicles live longer, your accountants smile more, and your operations run smoother than a politician’s promise.

What Makes Traditional Fleet Maintenance Inefficient and Costly?

The classic fleet maintenance system works on the same principle as changing the smoke detector batteries every time Mercury changes its position in the sky. Vehicles are routinely serviced according to time-based manufacturer-specified intervals. This means that a perfectly running vehicle is forced to have maintenance while the one that is ‘screaming’ for service is purposely bypassed.

According to a 2025 analysis by Platform Science, unplanned downtime costs fleet operators roughly US $448 to $760 per day, per vehicle (source). Over-maintaining vehicles remains wasteful because parts are replaced while they still have useful life left and before the recommended mileage is reached.

Under-maintenance, on the other hand, lets wear-and-tear accumulate — increasing the risk of breakdowns that lead to costly vehicle downtime.

Eventually, those problems lead to breakdowns faster than a health inspector can shut down a questionable taco stand. Every unexpected breakdown causes a domino effect; dispatch is in a hurry, customers are angry, and revenue loss is approximately $1,000 per hour for just one commercial vehicle on the roadside.

The harsh truth is that companies spend a fortune on maintenance and still experience breakdowns because they treat symptoms based on a schedule, not on actual vehicle health monitoring. Fleet managers frequently wonder: “What percentage of our current maintenance spending is actually preventable waste?”

Studies show that 30-40% of traditional maintenance costs come from unnecessary service or missed critical repairs. Therefore, traditional fleet maintenance optimization is as scientific as reading tea leaves.

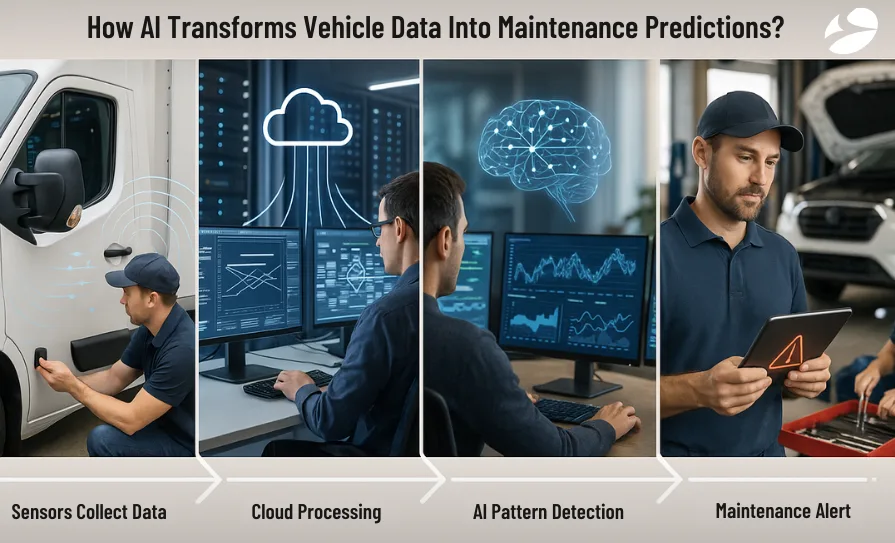

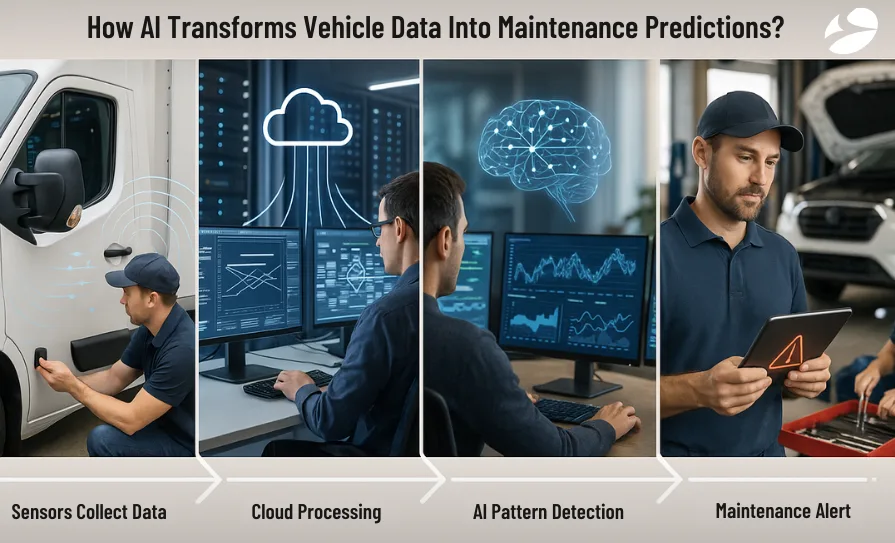

How Does AI-Based Predictive Maintenance Transform Fleet Management?

AI-powered predictive maintenance is redefining fleet efficiency by spotting issues long before they become costly problems.

IoT Sensors and Machine Learning Integration

Modern fleet vehicles are equipped with more sensors than a paranoid person’s home security system, except these actually serve a purpose beyond catching package thieves. IoT-powered fleet management turns every truck into a data-generating machine that reports everything from tire pressure to engine temperature faster than office gossip spreads about layoffs—data that a capable AI Development Company can transform into predictive insights, smarter routing decisions, and real-time maintenance intelligence that actually reduces downtime instead of just reporting it.

BiztechCS can integrate IoT sensors across your entire fleet, regardless of vehicle types or manufacturers, because discrimination based on make and model is so last century. Machine learning algorithms digest this data buffet and spot patterns that human mechanics would miss, even if you tattooed them on their eyelids.

Real-Time Performance Monitoring Capabilities

The modern era of Vehicle health monitoring is just skipping a stage of diagnosis by a doctor, where the doctor gets it wrong each and every time. However, in the end, the diagnosis is made, and it won’t be a disaster that would cost a lot of money, but a mere problem.

AI predictive maintenance systems monitor everything, synthesizing predicted car lifetimes and grouping them by possible failure causes. These insights reveal future issues that traditional inspections would never identify.

The beauty lies in tailoring your specific fleet pattern and operational requirements to develop custom algorithms, as cookie-cutter solutions work about as well as using a chainsaw for brain surgery.

Predictive Analytics for Failure Prevention

Predictive maintenance for fleets analyzes historical data and current performance metrics to forecast breakdowns. It does this with the accuracy of a fortune teller who actually went to engineering school.

The system identifies failure patterns weeks before components give up the ghost. This lets you schedule repairs during planned downtime instead of explaining to customers why their urgent shipment is taking a scenic detour to the repair shop.

This crystal-ball approach to fleet maintenance optimization reduces emergency repairs by up to 75%. Operations leaders often question: “Will our drivers and maintenance teams actually adopt this new technology?” Experience shows that once teams see the system preventing their first major breakdown, adoption becomes enthusiastic – nobody wants to go back to surprise 2 AM breakdown calls. It turns chaos into clockwork while your competitors are still playing automotive roulette.

Ready to transform your fleet from a maintenance money pit into a profit-generating machine? Smart fleet operators are already seeing 35% fewer breakdowns and wondering why they waited so long.

Stop Breakdowns Before They Happen

Use AI-driven predictive maintenance to cut downtime, reduce repair costs, and keep your fleet on the road.

What Are the Core Components of an AI Predictive Maintenance System?

An effective AI predictive maintenance system relies on several key components that work together to turn raw vehicle data into precise, proactive maintenance decisions, often built and optimized through ai/ml development services that ensure data accuracy, scalable model training, and real-time insight generation across complex vehicle ecosystems.

Real-Time Data Collection

IoT sensors are like surveillance cameras installed across the whole fleet, like surveillance cameras installed at the casino. Instead of detecting card counters, they log every glitch, cough, and mechanical uproar your cars make.

These digital informants monitor everything from engine heat to tire pressure. They report it faster than teenagers gossiping about who left the office last, only to get fired the previous week.

Vehicle health monitoring captures performance metrics, including vibrations that shouldn’t exist and fuel consumption that makes accountants cry. It also tracks emissions levels that determine whether you’re saving the planet or personally melting ice caps.

The data transmission infrastructure works harder than your IT department during a ransomware attack. It ensures every byte of information reaches your analytics platform without getting lost in digital purgatory.

Predictive Analytics Engine

The brain of AI predictive maintenance operates like Sherlock Holmes on steroids, finding patterns in data that would make statisticians weep with joy.

BiztechCS can implement machine learning models that continuously improve accuracy through historical data analysis. They get smarter with each breakdown, like a mechanic who’s seen every possible way a transmission can fail.

Pattern recognition catches anomalies before they turn into expensive surprises. Component-failure prediction models then forecast breakdowns with the precision of a Swiss watchmaker who moonlights as a psychic.

The system customizes prediction algorithms for your specific vehicle types and usage patterns. After all, treating all vehicles the same is like assuming all your employees work equally hard.

AI Expert Tip: Start your predictive maintenance journey by focusing on your highest-value or most problematic vehicles first. BiztechCS recommends implementing AI monitoring on 10-15% of your fleet initially to establish baseline patterns and prove ROI before full deployment. This phased approach typically shows 20% cost reduction within 90 days, making it easier to justify expansion across your entire fleet.

Automated Alert Systems

Priority-based alerts hit your maintenance team’s inbox like urgent emails from the board. The difference is that these actually matter and won’t waste three hours of your life in pointless meetings.

The system generates maintenance recommendations that tell you exactly what needs fixing and when to fix it. It also explains why waiting would be dumber than trying to save money by duct-taping brake lines.

Optimal scheduling suggestions prevent the maintenance bay traffic jams that occur when five trucks need service at the same time. They organize repairs with the efficiency of a wedding planner who’s also a drill sergeant.

These predictive maintenance alerts for fleets ensure problems are addressed by severity, not by whoever complains the loudest.

Cost Optimization Features

You won’t be investing money like a desperate player at a rigged slot machine by throwing it at problems. Instead, you’ll invest in maintenance, where it actually prevents disasters and benefits the company.

Lifecycle management insights help determine when vehicles should retire gracefully. They also show when they’re still alive and worth keeping, much like knowing when to cut off that old server no one wants to upgrade.

ROI tracking capabilities measure every penny saved through fleet maintenance optimization. They provide the complex numbers that make financial presentations less painful than a root canal without anesthesia.

The system transforms maintenance from a black hole of expenses into a strategic advantage. CFOs consistently ask: “What’s the typical payback period for this investment?” Most organizations recover their initial investment within 12-18 months through reduced breakdowns, optimized parts inventory, and extended vehicle lifecycles. It proves that sometimes spending money intelligently beats praying to the reliable gods.

How Can BiztechCS Build Scalable AI Predictive Maintenance Solutions for Your Fleet?

Building a scalable predictive maintenance system starts with an approach that grows with your fleet and adapts to your operating practices.

Cloud-Native Architecture

BiztechCS develops cloud-based solutions that scale seamlessly as your fleet grows from 10 to 10,000 vehicles. Nobody wants to rebuild their entire system every time they buy another truck.

The architecture handles growth spurts better than a teenager’s wardrobe. It expands without dramatic meltdowns or astronomical replacement costs. The microservices approach also ensures each component works independently, so when one part needs updating, you don’t have to shut down the entire operation like performing heart surgery to fix a hangnail.

Real-time data processing for IoT-powered fleet management happens faster than your competitors can say “system overload.” It handles millions of data points without breaking a sweat or demanding overtime pay.

The cloud infrastructure scales up during peak seasons and down during slow periods. It adapts to your needs like a Swiss Army knife that somehow knows which tool you need before you do.

Custom Integration Capabilities

BiztechCS can integrate with your existing fleet management systems, ERP platforms, and maintenance scheduling tools without causing the digital equivalent of organ rejection.

The API-first development approach makes connecting systems smoother than a politician dodging difficult questions. It also ensures your current tech investments play nicely with ai/ml development services, especially when integrating AI-driven predictive maintenance capabilities without rebuilding your entire stack.

Sensor compatibility across vendors ensures the solution works with any hardware you already have installed. Forcing you to get rid of perfectly functioning equipment would be like demanding you replace all your office furniture just to buy new staplers.

The integration process takes your existing workflows and fits them in like a missing puzzle piece. It avoids the square-peg-in-a-round-hole situation entirely. IT executives frequently worry: “How much disruption will this cause to our current operations during implementation?” BiztechCS’s phased approach typically enables full integration with zero operational downtime, gradually rolling out features while your fleet keeps moving. This flexibility ensures that vehicle health monitoring data flows smoothly between systems, creating a unified ecosystem rather than digital islands where information goes to die.

AI Expert Tip: Configure your AI system to learn from both normal operations and edge cases. Based on the discovery data, BiztechCS believes that training models on 6-8 weeks of baseline data captures seasonal variations and driver behaviors unique to your fleet. Set initial anomaly detection thresholds at 2-3 standard deviations, then fine-tune based on false-positive rates to achieve optimal alert accuracy without overwhelming your maintenance team.

Industry-Specific Solutions

BiztechCS can build specialized predictive maintenance for fleets, whether you’re running delivery vans, field service vehicles, construction equipment, or public transportation systems. Some of those systems carry more drama than a reality TV show.

Each industry has quirks that generic solutions miss entirely. Construction equipment generates dust that could choke a vacuum cleaner, while delivery fleets endure stop-and-go torture that ages engines in dog years.

Customized dashboards show exactly what matters to your operations. They don’t rely on some generic template that’s about as useful as a chocolate teapot in the desert.

Compliance and regulatory requirements are integrated into the system from the start. This ensures your fleet maintenance optimization passes every bureaucratic check without the need for a lawyer to interpret the reports.

The solution can handle your specific operational hell. That includes managing refrigerated trucks with strict temperature control or emergency vehicles where downtime is literally measured in lives.

Which Industries Benefit Most from AI-Powered Fleet Maintenance?

AI-powered fleet maintenance brings game-changing reliability to industries where every minute of uptime directly impacts revenue, safety, and customer satisfaction.

Delivery and Logistics Companies

Delivery fleets operate on a schedule tighter than that of a surgeon conducting back-to-back operations. A single breakdown during rush hour can trigger a wave of late deliveries that makes customers angrier than wasps at a picnic.

AI predictive maintenance keeps vehicles running during the holiday rush, when package volume increases like popcorn in a microwave. It also prevents mechanical failures that turn same-day delivery promises into next-week apologies.

Route efficiency improves naturally when trucks aren’t making surprise detours to repair shops. This lets fleet maintenance optimization actually mean something besides crossing fingers and praying to the logistics gods.

Field Service Organizations

Field service vehicles breaking down on the way to fix someone else’s equipment creates an irony so thick you could cut it with a plasma torch.

Vehicle health monitoring ensures technicians actually reach customer sites instead of becoming roadside statistics. Nothing destroys customer satisfaction metrics faster than your repair person needing a rescue of their own.

IoT-powered fleet management keeps service response times shorter than the average attention span in the TikTok era, especially when supported by an AI Development Company that understands real-world operational data. AI-driven predictive maintenance also prevents the embarrassing phone calls explaining why the person sent to fix problems is now part of the problem—by spotting failures before they ever reach the road.

Public Transportation Systems

Public buses that break down during rush hour cause commuter rage that makes road rage look like meditation class. These breakdowns create PR nightmares that trend on social media faster than celebrity scandals.

Scheduled maintenance optimization through predictive maintenance keeps vehicles operational when thousands depend on them. It prevents the service reliability disasters that end up on the evening news.

Public safety considerations mean catching brake issues before they become lawsuits. Explaining mechanical failures to regulatory bodies is about as pleasant as a colonoscopy performed by an angry wolverine.

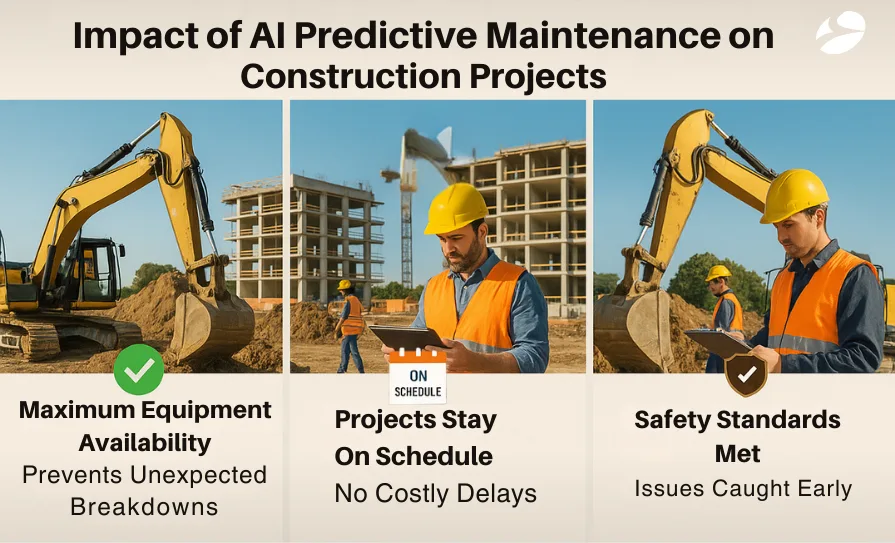

Construction and Heavy Equipment

Construction equipment that dies mid-project creates delays that cascade through schedules like dominoes made of money, each fallen deadline costing more than the last.

Equipment utilization maximization means your million-dollar machines actually work instead of becoming the world’s most expensive lawn ornaments. Construction executives often ask: “Can the system handle our mixed fleet of different equipment brands and ages?” The beauty of modern AI predictive maintenance is its adaptability – whether your excavator is brand new or older than your newest hire, IoT sensors can be retrofitted to monitor any equipment with moving parts. At the same time, project deadline protection prevents you from having to explain to clients that their building won’t be ready until the next century.

Safety compliance management through AI/ML development services–powered predictive maintenance catches issues before OSHA inspectors do, because nothing ruins profit margins quite like shutting down operations for violations that proper maintenance would have prevented.

AI Expert Tip: For mixed-age fleets, prioritize sensor deployment based on maintenance history rather than vehicle age. Our data shows that retrofitting IoT sensors onto vehicles with 3+ years of maintenance records yields 40% better prediction accuracy than starting from scratch. Focus on high-failure components first—engine, transmission, and hydraulics typically account for 70% of unexpected downtime in heavy equipment.

Closing Lines

Fleet maintenance has evolved from hoping your vehicles survive another day to actually knowing they will, which beats sacrificing goats to the reliability gods any day of the week.

AI predictive maintenance transforms fleet operations from expensive guessing games into data-driven precision. It cuts costs by 40% while making breakdowns as rare as honest campaign promises.

The industry now stands at a crossroads. Companies must either adopt vehicle health monitoring technology or continue burning money faster than a startup with unlimited venture capital.

Those who embrace IoT-powered fleet management today will watch their competitors struggle to explain to shareholders why they’re still using maintenance schedules from the Stone Age.

BiztechCS, an experienced AI Development Company, is ready to help transform your fleet operations with custom AI predictive maintenance solutions that actually work. They’re far more reliable than the magic 8-ball your maintenance manager secretly consults.

Let’s build a smarter, more efficient future for your fleet together. The only thing worse than change is watching your competition leave you in their exhaust fumes while your trucks sit broken on the roadside.

Every day without predictive maintenance is another roll of the dice with your operational efficiency. Is your fleet ready to predict problems before they cost you thousands? Find out now.

Ready for a Smarter Fleet?

Turn vehicle data into real-time insights and prevent costly failures before they disrupt operations.

5 min read