294

What Makes Odoo the Right Manufacturing ERP Solution for UAE Factories?

5 min read

294

5 min read

Factory floors in the UAE have become the digital age’s comedy of errors. Production managers juggle spreadsheets like circus performers. Quality control teams play telephone with data across disconnected systems. The result? Manufacturing facilities operate like they’re stuck in a bad sitcom rerun.

According to a 2024 global manufacturing study, 65% of manufacturers say they are lagging in digital transformation efforts. Many of these organizations risk falling behind without significant technology upgrades. This challenge closely mirrors what the UAE’s industrial sector is experiencing as it accelerates toward smarter, more connected operations (source).

One industrial goods manufacturer in Dubai discovered this the hard way. Their production line moved more slowly than traffic on Sheikh Zayed Road during rush hour. Orders piled up like unread emails. Quality issues slipped through cracks wider than the gap between their systems. Sound familiar? This manufacturer decided enough was enough.

They integrated Odoo into their manufacturing operations in the UAE, and production speed increased by 30%. The Odoo ERP for the manufacturing industry didn’t just connect its systems; it also integrated them. It turned their operational chaos into orchestrated efficiency.

Manufacturing ERP software implementations in the UAE usually promise the moon. This one actually delivered. Here’s how they transformed their Odoo production management setup in the UAE from a nightmare into a well-oiled machine.

UAE manufacturers are operating in a high-growth, high-pressure environment. Legacy processes are struggling to keep pace with rapid market demands, rising compliance standards, and the ongoing push toward digital transformation.

UAE factories run more disconnected apps than a teenager’s phone. Production software refuses to talk to inventory systems while quality control tools sulk in their own corner like moody siblings at a family dinner.

A major aluminum manufacturer in Jebel Ali discovered that its production team was making decisions based on three-day-old inventory data, essentially driving while looking through a rearview mirror covered in dust.

Production schedulers in the UAE play a daily game of Tetris with Excel sheets that crash more often than a learner driver in a parking lot. When material availability changes faster than Dubai’s skyline, these poor souls manually adjust schedules as if they were defusing a bomb with chopsticks.

One textile manufacturer calculated they lost AED 2.3 million annually just from production delays caused by their scheduling guesswork, making their planning process more expensive than a weekend brunch at Atlantis.

At this point, manufacturing executives often ask: ‘How long does it typically take to connect all these disconnected systems?’ The answer varies, but most Odoo integrations in UAE factories achieve full system connectivity within 8-12 weeks.

The key is starting with the most critical pain points first – usually production and inventory – then expanding to other departments once the initial integration proves its worth.

Quality inspectors armed with clipboards and tired eyes miss defects like referees miss fouls in a heated football match. Products with issues travel through the production line longer than tourists lost in the Gold Souk, only to be caught when it’s too late and too expensive.

Compliance standards change faster than fashion trends, leaving manufacturers scrambling to update manual processes that move slower than government paperwork. This is precisely why smart companies are exploring Odoo’s quality control module.

Are your quality control processes still living in the clipboard era while your competitors embrace digital precision? It’s time to stop letting defects slip through the cracks and start building quality into every step of your production.

We’ll evaluate your current production systems, uncover hidden efficiency gaps,

and create a phased Odoo implementation roadmap tailored to your factory floor.

In a market defined by speed, scale, and constant change, integration is no longer a technical upgrade but a strategic necessity for manufacturers aiming to stay competitive in the UAE.

Waiting for department updates in manufacturing is like waiting for rain in the desert – technically possible but painfully unrealistic. Real-time data synchronization turns your factory floor into a Formula 1 pit crew where everyone knows exactly what’s happening without shouting over machinery or sending carrier pigeons disguised as emails.

We at BiztechCS can implement real-time data integration solutions seamlessly that connect all your manufacturing processes. Because watching departments actually communicate effectively is more satisfying than finding parking at Dubai Mall on a Friday.

UAE manufacturers without integrated systems compete like marathon runners wearing ski boots – technically moving forward but definitely not winning any medals.

Manufacturing ERP software implementation in the UAE slashes time-to-market faster than a hot knife through hummus. At the same time, meeting international quality standards becomes as smooth as a freshly paved Emirates Road.

Cost reduction through efficiency isn’t just corporate poetry anymore; it’s real money saved that makes your accountants smile wider than tourists seeing the Burj Khalifa for the first time.

Business owners frequently wonder: ‘What’s the actual ROI timeline for implementing manufacturing ERP in the UAE?’ Based on regional implementations, most manufacturers see positive returns within 14-18 months, with operational cost reductions of 15-25% in the first year alone.

The faster time-to-market and reduced quality issues contribute to revenue gains that often exceed the initial investment by the second year.

Growing your manufacturing operation without scalable systems is like building a skyscraper on sand – entertaining to watch but destined for disaster.

Multi-location facilities need Odoo production management solutions in the UAE that expand like elastic waistbands after an Iftar feast, handling increademandands without breaking a sweat or your budget.

We at BiztechCS can develop scalable Odoo solutions that grow with your business needs, ensuring your system scales smoother than a fish in the Arabian Gulf rather than flopping around like one on the beach.

Is your current manufacturing system ready to handle your ambitious growth plans, or will it become the bottleneck that holds you back? The right ERP foundation today determines whether you’ll be leading the market or playing catch-up tomorrow.

Get a clear view of where your manufacturing systems are slowing you down

and receive a practical Odoo-driven roadmap to boost productivity and control.

Odoo replaces fragmented workflows and manual guesswork with a single intelligent platform. This enables manufacturers to gain tighter control, faster decision-making, and measurable efficiency across the entire production lifecycle.

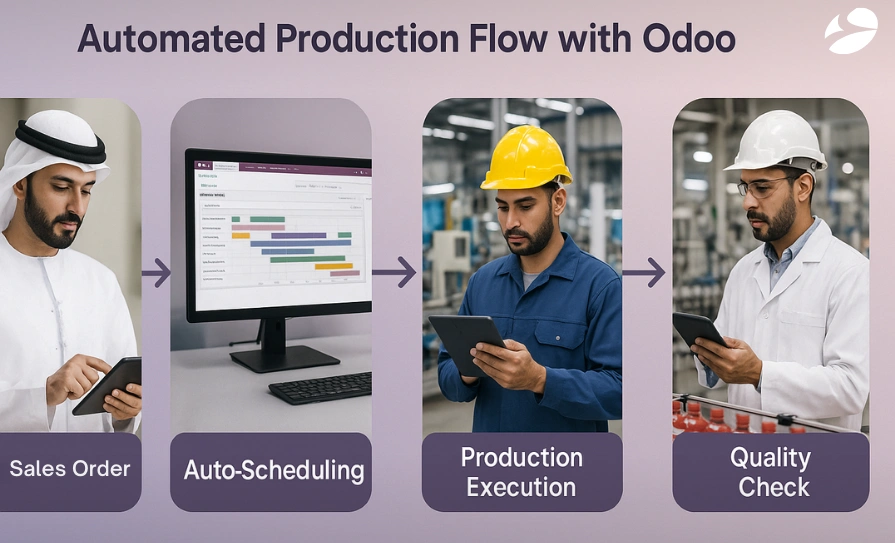

Odoo ERP for the manufacturing industry turns sales forecasts into production schedules faster than a GPS rerouting traffic in Dubai during National Day celebrations. Material requirement planning stops being a guessing game where planners throw darts blindfolded at a board covered in sticky notes and prayer.

Dynamic schedule adjustments happen automatically when orders change, instead of production managers having panic attacks that make stock traders during a market crash look calm and collected.

Operations leaders naturally ask: ‘Will our production staff need extensive training to use these automated systems?’ The beauty of modern Odoo implementations is their intuitive design – most floor workers master the basics within a week, while supervisors typically need 2-3 weeks to leverage advanced features.

The system’s user-friendly interface means your team spends less time learning software and more time improving production.

Real-time stock tracking with Odoo for manufacturing UAE means knowing exactly what’s in your warehouse without sending search parties armed with flashlights and hope.

Automated reorder points trigger purchases before your inventory hits zero. Unlike the current system, someone only notices you’re out of materials when the production line stops moving like a camel that decided to take a nap.

Material usage optimization ensures every scrap gets utilized properly. It turns waste reduction from a fairy tale told at board meetings into actual numbers that make finance teams weep tears of joy.

The Odoo quality control module configures inspection points that catch defects faster than security at the airport catches water bottles. Automated flagging systems highlight issues before they multiply like construction projects in Business Bay, saving both money and sanity.

Compliance documentation generates itself while you sleep, replacing the current nightmare where quality teams manually create reports that take longer to complete than building the Palm Jumeirah.

A structured, phased approach ensures automation delivers real results without disrupting ongoing production, while aligning technology with your operational and compliance goals.

BiztechCS can transform your production chaos into orchestrated efficiency faster than a Formula 1 pit stop.

We can implement Odoo’s Manufacturing module to convert your sales forecasts into production orders automatically, ending the daily ritual of manual scheduling that causes more headaches than a construction site at 6 AM.

Our team can configure automatic work order generation from sales orders, making your production planning smoother than silk road trade routes minus the bandits. We can set up real-time inventory updates that give your production teams instant visibility without playing hide-and-seek in warehouses.

BiztechCS can eliminate those last-minute schedule adjustments that make production managers age faster than milk in the desert. Material shortages become ancient history when we implement Odoo production management UAE solutions. Your automated scheduling will run so smoothly, competitors will think you’ve discovered time travel.

Factory owners consistently raise the concern: ‘How much production disruption should we expect during implementation?’ With BiztechCS’s phased approach, disruption stays minimal – typically less than 5% productivity impact during the transition.

We run parallel systems initially, switching over during planned maintenance windows or low-production periods. Most clients report that any temporary slowdown is offset by immediate efficiency gains in the implemented areas.

We can integrate Odoo’s Inventory module with your manufacturing systems, creating connections as tight as airport security during peak season.

BiztechCS can establish automatic stock level updates during production, making manual counts as unnecessary as a chocolate teapot. Our team can configure low-stock alerts that notify procurement teams before crisis mode kicks in, unlike the current system, where running out of materials is a surprise party nobody wanted.

We can implement real-time tracking for raw materials and finished goods that follows every item like a helicopter parent, except this surveillance actually helps. Manufacturing ERP software UAE that we implement knows exactly what’s being consumed, when it’s happening, and predicts future needs better than a fortune teller with insider information.

BiztechCS can ensure your inventory levels update automatically as materials flow through production. The days of spreadsheet gymnastics and inventory guessing games will end faster than free samples at Carrefour.

BiztechCS can deploy the Odoo quality control module, like installing a truth detector in a world full of wishful thinking. We can define inspection points at critical production stages that catch defects before they multiply like parking violations in a busy mall.

Our automatic flagging systems for non-conforming products can work more efficiently than speed cameras on Sheikh Zayed Road, except that these actually prevent problems instead of just documenting them. We can create standardized quality documentation processes that generate reports automatically while your quality team focuses on improvements instead of paperwork.

BiztechCS can replace the chaos where every inspector follows their own rulebook with standardized processes everyone actually understands. Compliance requirements can be met automatically when we set up your system, turning audit preparation from a three-alarm fire into a routine check.

Our quality control setup ensures your products meet standards consistently, not just when inspectors remember to look.

Odoo’s flexible, modular architecture enables it to adapt to a wide range of manufacturing environments. This makes it especially effective across diverse UAE industry segments with varying operational complexities.

Heavy machinery producers in the UAE juggle more moving parts than a Swiss watch assembled during an earthquake. Construction material manufacturers deal with specifications that change more frequently than weather predictions, making their production planning feel like building sandcastles during high tide.

We at BiztechCS can customize Odoo for complex industrial manufacturing needs, turning your chaotic assembly lines into symphony orchestras where every component arrives on cue, rather than fashionably late like guests at a wedding reception.

FMCG manufacturers race against expiry dates like they’re defusing bombs while textile factories manage color variations that would make a rainbow jealous. Electronics assembly lines in the UAE move faster than gossip at a company merger, requiring Manufacturing ERP software UAE that can keep pace without breaking a sweat.

Odoo for manufacturing UAE handles these high-speed operations better than a caffeine-powered robot. It tracks everything from thread counts to circuit boards without mixing up orders like a confused waiter during Iftar rush.

Pharmaceutical production requires precision that makes brain surgery look like finger painting, with compliance requirements thicker than a phone book from 1995. Food processing facilities balance quality control with speed like tightrope walkers juggling flaming torches above a pool of hungry sharks.

Chemical manufacturers need Odoo production management UAE solutions that track formulas more carefully than a paranoid chef guards secret recipes, ensuring batch consistency while maintaining safety standards that would make a helicopter parent proud.

Industry leaders in specialized sectors often question: ‘Can Odoo really handle our unique regulatory requirements and complex processes?’ The platform’s modular architecture enables industry-specific customizations that meet ESMA, Dubai Municipality, and international standards, including ISO and FDA requirements.

Whether you’re tracking pharmaceutical batch numbers or managing halal certification processes, the system adapts to your compliance needs rather than forcing you into a generic framework.

The transformation from disconnected manufacturing chaos to integrated operations isn’t magic; it’s just what happens when systems actually talk to each other instead of giving each other the silent treatment. That Dubai industrial manufacturer went from production speeds slower than a snail on sedatives to 30% faster output, proving that Odoo for manufacturing UAE works better than caffeine injections directly into machinery.

Waste dropped by 20% because materials stopped disappearing into the black hole between departments, while quality issues became as rare as polite drivers during rush hour.

BiztechCS can optimize your manufacturing operations, whether you’re running a single production line that feels like herding cats or managing a global network that resembles a circus without a ringmaster.

We can design Manufacturing ERP software UAE solutions that turn your production nightmares into dreams so smooth, your competitors will check if you’ve hired wizards. Your factory floor doesn’t have to operate like a reality TV show where nobody knows what’s happening next.

Ready to transform your manufacturing chaos into competitive advantage? Your production floor deserves better than spreadsheet gymnastics and disconnected systems that make every day feel like crisis management.

Artificial Intelligence (AI)

309

By Nandeep Barochiya

Odoo

370

By Uttam Jain

Artificial Intelligence (AI)

663

By Nandeep Barochiya