2524

Why Manufacturers Are Replacing Spreadsheets with Odoo for Smarter Scheduling?

5 min read

2524

5 min read

Monday mornings were synonymous with one set of problems after another for the operations manager.

The fault of machines lying idle as workers were waiting for tasks to be assigned was actually last-minute orders, whose very existence would mean that the plan was discarded for the entire week.

Rescheduling was done on the fly, alongside the team, using confusing spreadsheets that just added to the chaos. Bottlenecks came in because of ill-timed schedules, and production would slow down and run deliveries late.

It wasn’t that everyone wasn’t trying hard enough. It was just that no system could keep pace. That was when they decided to consider Odoo ERP solutions to bring structure to the process. Soon, by introducing the production scheduling software and automated scheduling through Odoo implementation services, their chaos gained a coordinated flow.

In this blog, we shall look into coordinating production scheduling, resource allocation, and production lines using the Odoo ERP for manufacturing, and how it effectively addresses these industry challenges.

1. Reliance on Spreadsheets and Legacy Systems

Manual entry is still the order of the day in many manufacturing setups. Teams are still using spreadsheets to maintain their schedules, often copying the exact piece of information across multiple files.

Errors creep in, and updates are missed. Outdated tools fail when further operated in complex scenarios. Even the small and trivial ones become checkpoints for their schedules with the passage of time.

2. Lack of Real-Time Visibility into Resource Availability

When no one precisely knows the status of machines or resources, planning becomes a matter of speculation. The machine is actually down, but the schedule assumes it is running. The labor may be overbooked, but the system does not reflect it.

Whatever choices are made, they are either delayed or improper due to the absence of real-time data. Here, a scheduling program in real time would be a real game-changer.

3. Inflexibility in Responding to Sudden Changes in Demand

Production plans change abruptly. A rush order might prioritize the latest order, or the customer might cancel an order on the last day.

But these traditional systems just don’t adjust quickly. Shifting resources or tasks takes longer, and that delay often leads to missed opportunities or stress for the teams.

4. Poor Communication Across Departments

Departments work within their own silos via disconnected tools. Production has no idea when raw materials arrive, and inventory forgets to update the shop floor in time. This translates to confusion, duplicated efforts, and mismatched schedules. A manufacturing execution system acts as a bridge to close this communication gap.

5. Limited Forecasting and Predictive Capabilities

One can hardly forecast if there are no insights provided by systems. Opportunities for maintenance are not foreseen until a machine ceases operation, while a shortage of raw materials is realized only when the warehouse is already empty.

A factory that does not embrace prediction goes reactive, and reacting has its own costs in terms of time and money.

1. Increased Downtime and Idle Equipment

Idle machines result from schedules that do not conform to reality. A few minutes of scheduling error can also mean hours of lost production.

The teams stand idle, awaiting new instructions or materials. Downtime-type incidents become part of the norm and hamper delivery and production.

2. Misallocation of Labor and Material Resources

Labor or material resources arrive at the wrong place at the wrong time. Workers are underutilized but sometimes overly stretched. Material resources may be excessively stocked or absent when required, leading to additional costs and wasted effort. Resource allocation software would eliminate such scenarios.

3. Missed Deadlines and Delayed Deliveries

Production constraints are immediately felt further down the line. This results in finished goods not being shipped on time. It starts to test the patience of clients. Such delays ruin reputation and relationships. Recovering from such speedy traps will, of course, take a lot of time and money.

4. Higher Operational Costs

Changes at the very last moment are far expensive. Overtime hours, rush deliveries, and wastage pile up terribly. When planning is poor, it entails working in emergency situations. Over time, the cost of these situations will become greater than the savings made from using basic tools in the first place. After all, profit margins are affected, and stress levels increase!

5. Reduced Overall Productivity and Efficiency

Any and all outputs suffer when the system does not support the work. Teams might work very hard, but the result is slow movement towards objectives. Instead of clarity, confusion manifests. The entire operation feels like it’s stuck. When we don’t have reliable tools, heading forward with power and efficiency surely seems impossible.

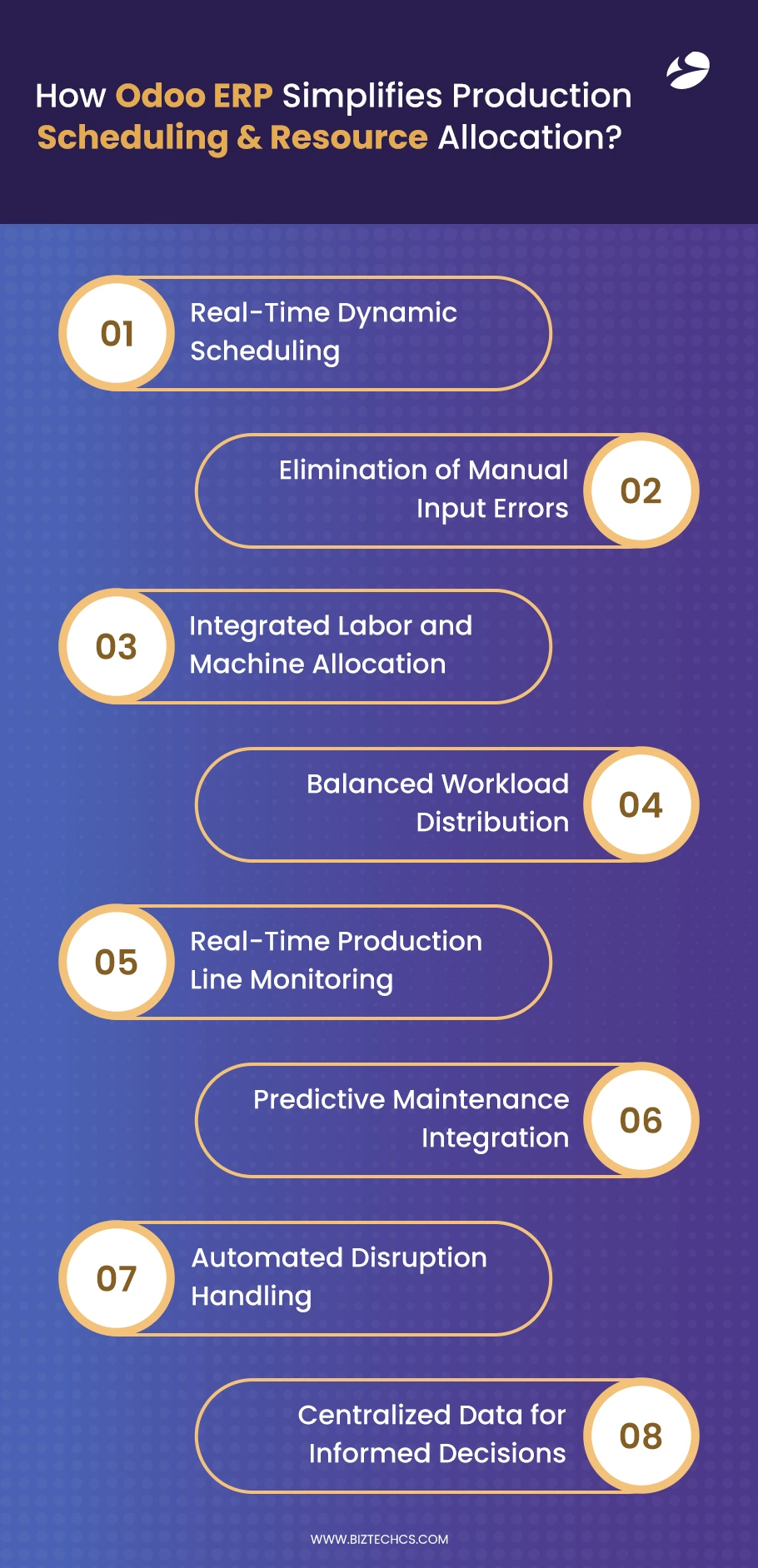

1. Real-Time Dynamic Scheduling

Just about every hour sees a schedule change. One particular machine is available now but won’t be available after two hours. Workers are on the shift; however, tomorrow they’ll be off. Odoo would respond to these changes at the moment they occurred. It gathers real-time information from the shop floor and automatically creates and modifies schedules. It means that there’s no need to adjust every task or shift manually.

Just about every hour sees a schedule change. One particular machine is available now but won’t be available after two hours. Workers are on the shift; however, tomorrow they’ll be off. Odoo would respond to these changes at the moment they occurred. It gathers real-time information from the shop floor and automatically creates and modifies schedules. It means that there’s no need to adjust every task or shift manually.

This is when Odoo’s manufacturing module really shines: Each job is slotted in at the appropriate time under the current conditions.

2. Elimination of Manual Input Errors

Prior to Odoo, schedules were manually made. That involved copying and pasting from file to file and repeatedly double-checking entries. One misplaced digit could cause a significant delay. Odoo substitutes those processes with built-in rules and automation.

Prior to Odoo, schedules were manually made. That involved copying and pasting from file to file and repeatedly double-checking entries. One misplaced digit could cause a significant delay. Odoo substitutes those processes with built-in rules and automation.

The system alerts for discrepancies and automatically resolves them. Errors diminish, and trust in the schedule improves. The outcome is more streamlined coordination with much less backtracking.

3. Integrated Labor and Machine Allocation

They knew which employee was available and which machine was available to take several calls and emails. With Odoo, that information is already linked. The system draws from HR to monitor labor and maintenance to monitor machines. This means only available and authorized resources are allocated.

They knew which employee was available and which machine was available to take several calls and emails. With Odoo, that information is already linked. The system draws from HR to monitor labor and maintenance to monitor machines. This means only available and authorized resources are allocated.

There is no guessing and no overbooking. Each job receives the proper team and equipment. It’s intelligent, linked manufacturing resource planning at work. For businesses looking to set this up, working with an experienced Odoo development company ensures the system is configured accurately to match real-world workflows.

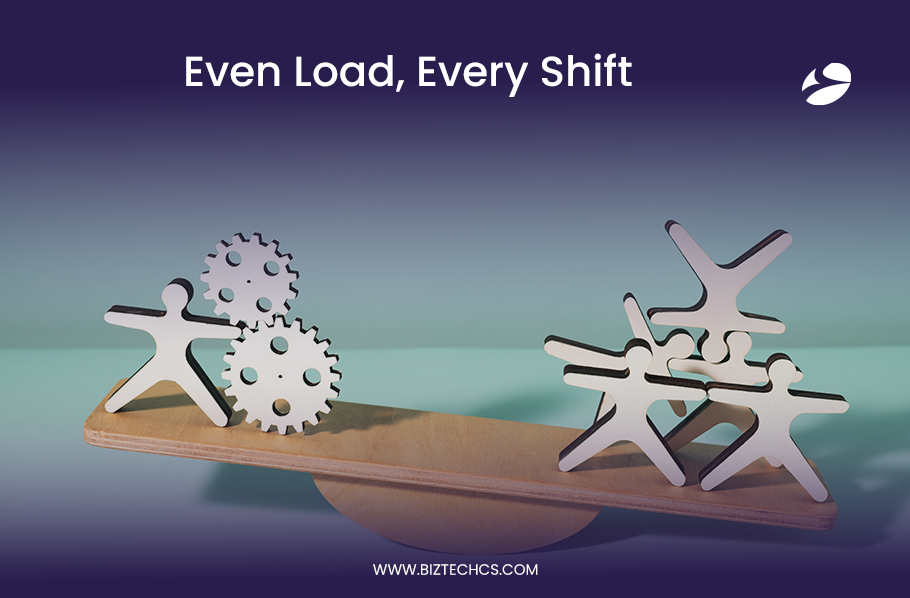

4. Balanced Workload Distribution

Certain machines ran continuously while others remained idle. Workers would sometimes find themselves overburdened, while others would have nothing to do. Odoo rectifies that unevenness. It distributes the workload according to real-time availability and work priority.

Certain machines ran continuously while others remained idle. Workers would sometimes find themselves overburdened, while others would have nothing to do. Odoo rectifies that unevenness. It distributes the workload according to real-time availability and work priority.

No resource is pushed beyond its capacity or made to wait. Every shift becomes more routine and productive. With the Odoo manufacturing module, you have a system that anticipates and gets everything rolling.

5. Real-Time Production Line Monitoring

Managers must observe what’s occurring on the floor today, not tomorrow. Odoo provides them with that visibility. Every production stage is followed in real time. If a production stalls, it’s highlighted at once.

Managers must observe what’s occurring on the floor today, not tomorrow. Odoo provides them with that visibility. Every production stage is followed in real time. If a production stalls, it’s highlighted at once.

That allows teams to respond before a minor delay becomes an issue. Production status isn’t buried in reports anymore. This type of visibility shifts how production line management software is designed.

6. Predictive Maintenance Integration

Machines don’t fail without warning—they indicate. Odoo monitors those indicators. It applies sensor readings and history to anticipate when maintenance is required. That way, service precedes failure. Schedules are automatically adjusted so nothing gets behind. This planning saves time and money. It’s not reactive—it’s governed and predictable.

Machines don’t fail without warning—they indicate. Odoo monitors those indicators. It applies sensor readings and history to anticipate when maintenance is required. That way, service precedes failure. Schedules are automatically adjusted so nothing gets behind. This planning saves time and money. It’s not reactive—it’s governed and predictable.

7. Automated Disruption Handling

Sudden changes once ruined entire plans. A faulty machine or a missing worker would hold up everything. Odoo recognizes the issue and corrects the plan. It rearranges tasks or reschedules jobs to maintain production flow.

Sudden changes once ruined entire plans. A faulty machine or a missing worker would hold up everything. Odoo recognizes the issue and corrects the plan. It rearranges tasks or reschedules jobs to maintain production flow.

Alerts are sent immediately. There is no waiting for someone to manually fix them. This is where production scheduling software is more than just software; it is an operational ally.

8. Centralized Data for Informed Decisions

Information used to reside in various systems, which really bogged down decision-making. With Odoo, everything is central. You can monitor resource availability, job status, and maintenance status—all in the same view.

Information used to reside in various systems, which really bogged down decision-making. With Odoo, everything is central. You can monitor resource availability, job status, and maintenance status—all in the same view.

The system paints the entire picture. That helps you move more quickly and in the right direction. Decisions are quicker, and operations remain on course.

1. Improved Operational Efficiency

Time is lost on the shop floor because of manual work. Odoo changes this through scheduling automation and real-time updates. The team doesn’t wait to get approval or a printed schedule anymore. Tasks are assigned instantly and can be tracked until completion.

There are fewer errors from manual data entry. Everyone knows exactly what they are supposed to do and when they are supposed to do it. It brings a different kind of clarity to daily operations.

2. Cost Reduction

Downtime means costs, which Odoo tries to minimize as much as possible. It sends machines and labor to areas where they are needed most, minimizing waste and allowing smooth product flows.

It detects errors and keeps one from having to do expensive rework. Better utilization of resources, not more. Eventually, one can actually see and prove that one has saved money.

3. Greater Agility in Production

Production plans can suddenly change when clients change deadlines or a machine stops working. Odoo changes the schedules and notifies all teams, instantly reassigning resources without the need to rebuild the entire plan from scratch. This kind of agility keeps production on its feet.

4. Enhanced Resource Utilization

Idle machines and overloaded teams are common problems. Thanks to Odoo, however, the situation has been made easier. It distributes the load between the equipment and the staff available. It tracks time, availability, and capacity in one interface. There is nothing to overlook. Tasks are given while keeping operations at a consistent flow. This kind of control would be difficult to attain without an automated scheduling system.

5. Scalable for Growth

With growth comes new lines, more products, and bigger teams. Managing this growth might get very complicated. Odoo manages it with simplicity. A big operation or just adding another location, the system again adjusts to the new needs.

It links all the data as operations grow. The teams don’t have to change from unfair midway through, making Odoo a reliable ERP for the manufacturing industry. With expert Odoo consulting services, manufacturers can scale their operations confidently while staying aligned with evolving business needs.

6. Centralized Data Access

Having this system in different places would just cause confusion. Different teams work from different files and tools. Odoo brings that all together. From inventory to production, data lives in one place.

That means there will be fewer miscommunications and faster decisions. Everyone will look at the same version of the truth, making it easy for the departments to work together.

7. Better Decision-Making

Decisions require facts, not guesses. Odoo provides real-time insights from the production floor. It monitors job progress, resource utilization, and potential delays. That information is simple to read and respond to. Leaders react quicker and plan better. It’s the advantage of an actual manufacturing execution system.

A Netherlands-based flag production company was increasingly having issues with its old website and operational applications. With increasing demand, they were finding it difficult to create a dynamic product configurator because their current system had limitations.

A Netherlands-based flag production company was increasingly having issues with its old website and operational applications. With increasing demand, they were finding it difficult to create a dynamic product configurator because their current system had limitations.

Shipping calculations were complicated, making delivery estimates inaccurately high in most cases. Pricing discrepancies caused confusion among customers and employees. Supplier communication had no structure, making their supply chain unreliable.

To address these problems, the company turned to Odoo and built a new system with a dynamic product configurator, automated DHL shipping, and an advanced pricing engine — all made possible through tailored Odoo customization services.

Consequently, the business experienced a 110% growth in total orders and a 65% increase in recurring purchases in a short timeframe.

An encoder for PVC-coated fabrics, supplying industries like architecture, transportation, and lifestyle, had severe production and inventory challenges as it expanded.

An encoder for PVC-coated fabrics, supplying industries like architecture, transportation, and lifestyle, had severe production and inventory challenges as it expanded.

The organization was using Excel to handle sophisticated tasks such as mixing pigments, coating, and quality control, which resulted in time wastage and constant errors. Tracking raw materials, particularly chemicals and pigments, was also inefficient, causing shortages or surpluses.

Quality control was done manually and unevenly, so it was difficult to sort by grade. Working with custom orders involving varying sizes and colors was a daily headache.

To address this, Odoo ERP was implemented with modules for manufacturing, inventory, quality, sales, and CRM, all unified through Odoo Integration services, allowing every department to work from the same data. This reduced production lead times by 25%, eliminated 20% of excess stock, and decreased product rejections by 15%.

Coordinating production schedules, resource planning, and production lines wasn’t always seamless. For most manufacturers, it all started with isolated tools and nonstop firefighting.

Spreadsheet mistakes brought everything to a crawl. Machines idled, employees idled, and orders were delayed.

With Odoo ERP for manufacturing, all that changed. Production was more predictable, inventory was more manageable, and quality was more consistent.

Real-world outcomes—such as a 25% reduction in lead times or a 20% reduction in overstock—prove this. When all parts of the process speak to one another, the whole operation can move in concert.

This level of transformation is achievable for any manufacturer with the right implementation approach, ensuring every feature is set up to deliver value from day one.

All product and company names are trademarks™, registered® or copyright© trademarks of their respective holders. Use of them does not imply any affiliation with or endorsement by them.

Artificial Intelligence (AI)

285

By Nandeep Barochiya

Odoo

332

By Uttam Jain

Artificial Intelligence (AI)

607

By Nandeep Barochiya