1211

Why Manufacturers in the UAE Struggle with Procurement and How Odoo Solves It?

5 min read

1211

5 min read

It’s 7 AM on a Tuesday in Dubai, and your production manager walks in with a familiar look of frustration. “We’re out of critical components again,” they say. “The supplier claims they never got our order, but I know we sent it last week.” If you’re in manufacturing, this probably hits close to home.

Procurement bottlenecks, missing orders, and endless back-and-forth with suppliers are more than just daily headaches—they’re problems that stall production and eat into profitability.

According to a survey from the Manufacturing Leadership Council, 70% of manufacturers still collect data manually. This reliance on manual workflows directly contributes to the breakdowns and delays you see in your supply chain (source).

When we first meet manufacturers struggling with procurement challenges, the conversation often starts with the same concerns. The Supply Chain Manager might say, “We’re using three different spreadsheets to track our orders, and somehow things still fall through the cracks.”

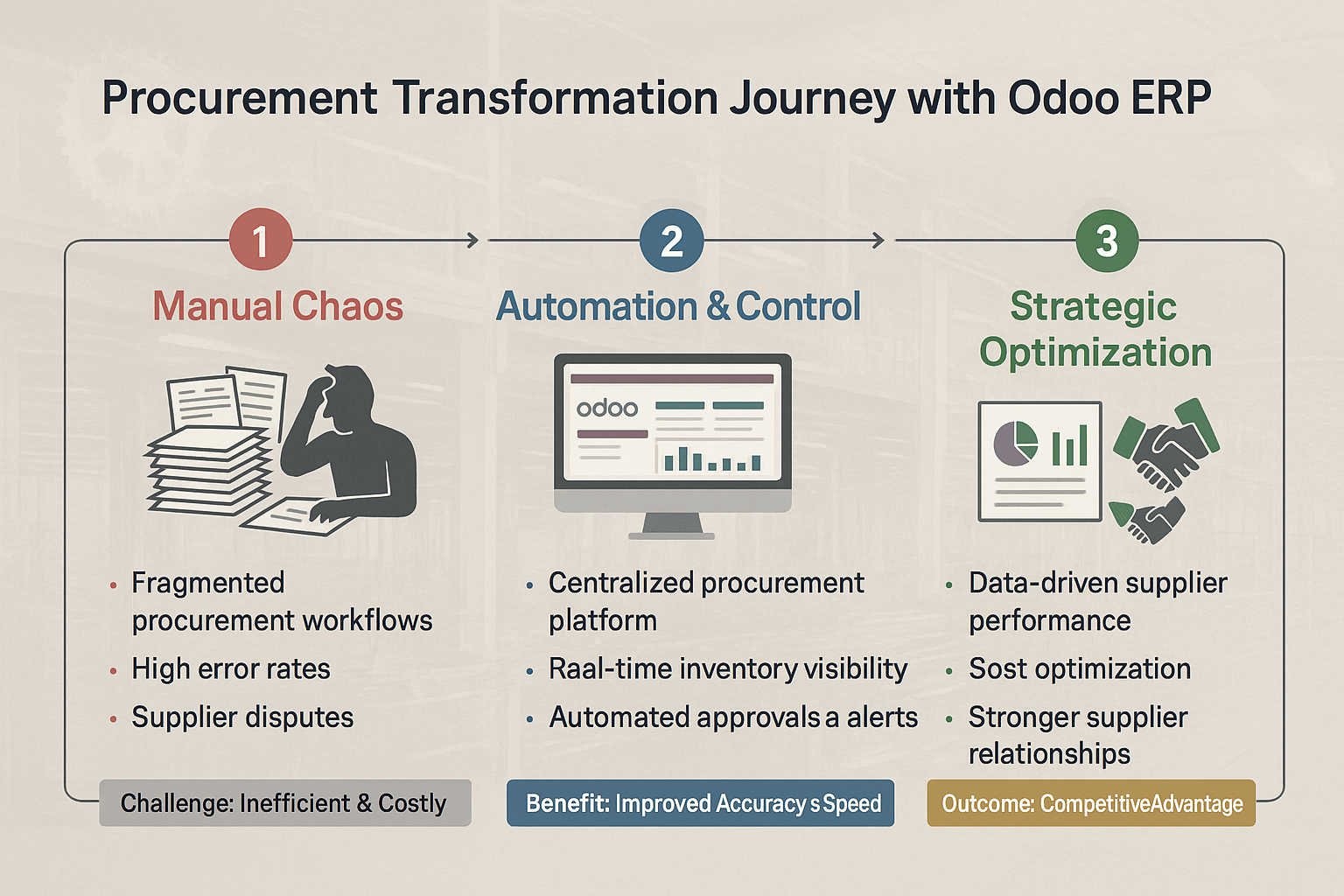

Here’s what typically happens in these fragmented systems:

When we first sit down with manufacturing leaders facing these challenges, we often ask: “How many different tools or systems does your team currently use to manage procurement? Are your purchasing decisions based on real-time data or educated guesses?” The answers usually reveal the true scope of the problem. And many executives quickly admit, “If we had a single source of truth for procurement data, our planning would look completely different.” That’s exactly what happens once manufacturers unify procurement data in Odoo—production schedules stabilize, firefighting reduces, and delivery commitments become far more reliable.

At BiztechCS, we’ve seen how manufacturers using disconnected procurement systems spend 40% more time on administrative tasks and experience 60% more supply chain disruptions than those with integrated solutions. This is where BiztechCS steps in to bridge that gap.

Odoo Consultant Tip: Always begin by mapping your top 3 recurring procurement bottlenecks before migrating to Odoo. This ensures the system is configured around your most urgent needs from day one.

The real tragedy isn’t just the immediate costs—it’s the missed opportunities. As you scramble to find missing components, your competitors with streamlined Odoo procurement management for manufacturers are capturing market share and building stronger customer relationships.

Every procurement challenge has a smarter solution. With BiztechCS, you can achieve a seamless ERP transformation that balances operational continuity with long-term impact.

Imagine walking into your procurement department and seeing every purchase order, supplier communication, and delivery status displayed on a single, real-time dashboard. This isn’t a distant dream—it’s what happens when you implement automated procurement with Odoo.

When BiztechCS works with manufacturers to transition to centralized procurement, we follow a proven methodology that unfolds like this:

BiztechCS will begin by configuring the Odoo purchase module for manufacturers to match your specific procurement workflows. We carefully migrate your existing supplier data, pricing agreements, and purchase histories into the new system, ensuring nothing is lost in the transition.

Here’s where BiztechCS delivers real transformation. We set up automated purchase order generation based on your minimum stock levels, production schedules, and supplier lead times. No more manual tracking or forgotten reorders. A common concern we hear from procurement heads is, “But what if suppliers suddenly extend lead times or adjust pricing—will automation still hold up?” The answer is yes. Odoo recalculates schedules in real time, flags exceptions instantly, and alerts managers before disruptions spiral into full-blown production delays.

BiztechCS will ensure your procurement team masters the new system through hands-on training sessions designed around their daily tasks, making the transition smooth and confidence-building.

Odoo Consultant Tip: When setting up automated workflows, configure supplier lead times realistically. Many businesses set overly optimistic timelines, which results in false expectations and frustrated production teams.

Consider this scenario: Your production team needs 500 units of a critical component by next Tuesday. In the old system, this would trigger a chain of phone calls, email searches, and manual calculations. With Odoo’s centralized procurement:

During our initial assessments, we often ask manufacturing teams a simple question: “When was the last time a supplier delivery arrived exactly when you expected it? How much time does your team spend chasing order statuses?” The responses typically reveal hours of wasted effort daily. And that naturally raises another reflection from COOs we work with: “If my team wasn’t wasting hours chasing updates, what higher-value tasks could they focus on?” With Odoo automating notifications and tracking, that reclaimed time gets redirected into strategic supplier negotiations, continuous improvement, and customer-focused initiatives.

This is precisely why BiztechCS recommends starting with your top 20% of suppliers (who typically represent 80% of your procurement volume) when implementing the Odoo purchase module. This approach delivers immediate impact while allowing your team to adapt gradually, ensuring a smooth transition that doesn’t disrupt your operations.

According to APQC’s Open Standards Benchmarking data, companies that automate procurement processes reduce purchase order cycle times by 46%, cutting the median from 35 hours to 24 hours (Procurify).

The moment you can answer “How much inventory do we have?” with absolute confidence is the moment your manufacturing operation transforms from reactive to proactive. This is what Odoo inventory management for manufacturing delivers.

When we meet with manufacturers, we frequently hear this concern: “We’ve tried inventory systems before, but they never stay accurate.” We understand this skepticism because we’ve seen it countless times. The difference with how BiztechCS will implement Odoo lies in our integration approach.

Instead of treating inventory as a separate system, Odoo connects it directly to,

Odoo Consultant Tip: Use barcode scanning from day one. Many manufacturers postpone it until later phases, but early adoption drastically improves accuracy and builds user trust in the system.

BiztechCS will help you establish clear location hierarchies and implement barcode scanning for accurate tracking. We ensure every component, raw material, and finished product gets a digital identity that integrates seamlessly with your operations.

BiztechCS connects your current MRP or production planning tools with Odoo’s inventory module, ensuring data flows automatically between systems without disrupting your established workflows.

BiztechCS will introduce advanced features like lot tracking, expiration date management, and multi-warehouse operations based on your specific manufacturing requirements, always with an eye toward scalability.

Here’s a common scenario we encounter: a manufacturer discovers they have three different inventory counts for the same component—one in their ERP, one in Excel, and one in the warehouse manager’s notebook. Sound familiar? At this point, CFOs often ask, “How much risk are we carrying by making production decisions on such conflicting numbers?” The risk is enormous, ranging from stockouts to over-purchasing. With Odoo’s integrated inventory management, those risks disappear because every update flows in real time across procurement, production, and warehouses.

With streamlined supply chain management using Odoo, accuracy becomes automatic through our proven methodology:

During our consultations, we always ask: “How often do you conduct physical inventory counts? What percentage variance do you typically find between your system records and actual stock?” These questions help us assess the current state of accuracy.

At BiztechCS, we’ve consistently observed manufacturers improving inventory accuracy from 75–80% to 95–98% within just three months of implementing integrated inventory management with our methodology. This transformation happens because we address the root causes of inaccuracy—not just the symptoms.

And the stakes are high: inventory carrying costs typically amount to 20–30% of a company’s total inventory value every year (Investopedia). Reducing this burden while improving stock visibility can free up capital, improve cash flow, and ensure customers get what they need when they need it.

Ready to explore how real-time inventory visibility could transform your manufacturing operations? Let’s look at what happens when supply chain complexity meets integrated ERP solutions.

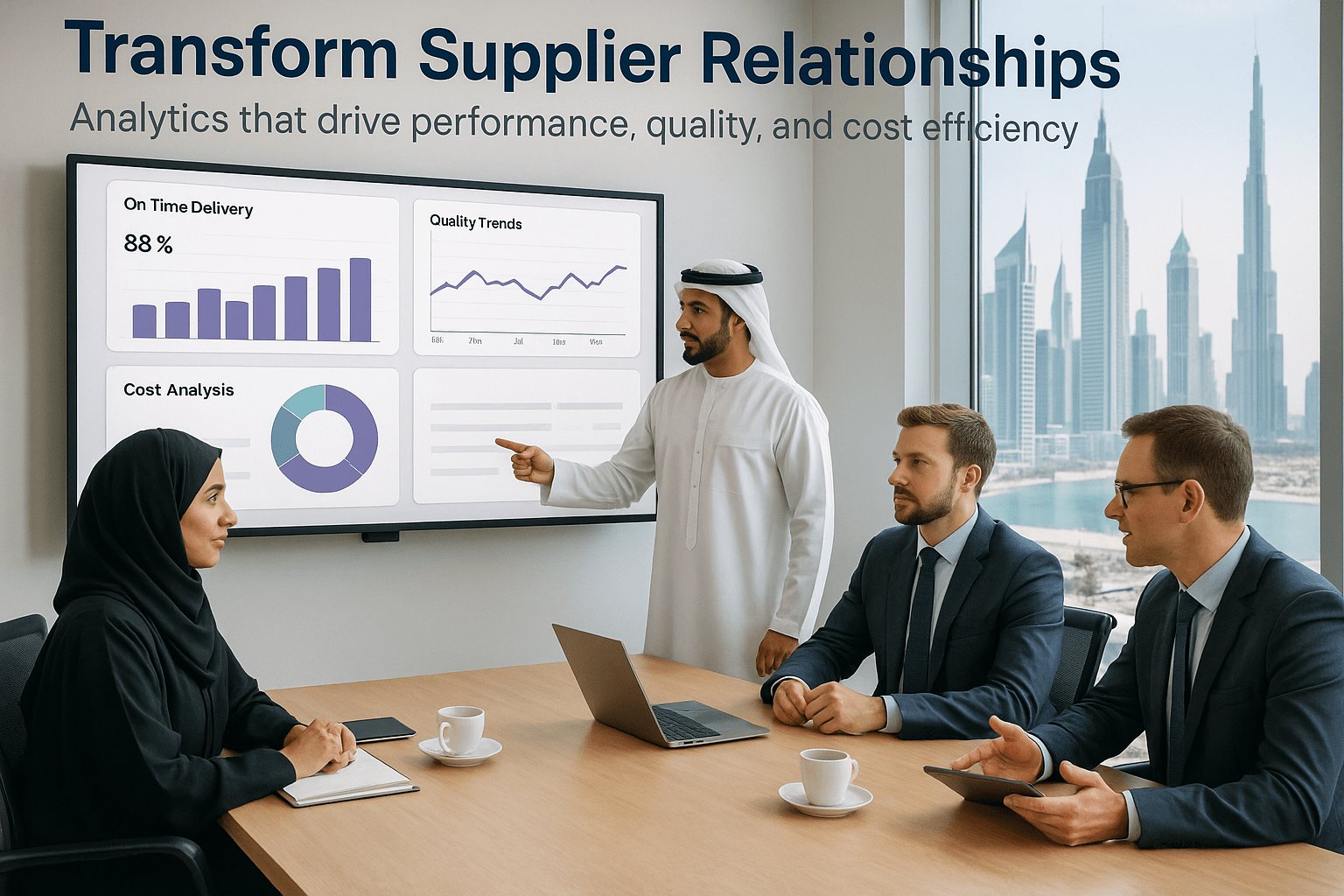

Your suppliers are partners in your success, but are you managing these relationships with the strategic importance they deserve? Most manufacturers we encounter treat supplier management as an administrative task rather than a competitive advantage.

Traditional supplier management often looks like this:

Which is why procurement leaders often tell us, “Imagine if I walked into negotiations with live supplier performance data instead of outdated averages—how different would that conversation be?” The difference is night and day. With Odoo dashboards, negotiations shift from vague discussions to evidence-backed conversations, enabling manufacturers to secure better terms, hold suppliers accountable, and even collaborate on innovations. Odoo procurement management for manufacturers transforms this approach by providing real-time insights into every aspect of supplier performance.

Odoo Consultant Tip: When setting up supplier profiles, include both quantitative metrics (on-time delivery, quality) and qualitative notes (responsiveness, innovation support). This balanced view makes your supplier strategy far more effective.

Imagine walking into a supplier negotiation armed with precise data,

This isn’t just data collection—it’s strategic intelligence that transforms how you build supplier relationships.

BiztechCS will help you establish comprehensive supplier profiles that go beyond basic contact information to include performance metrics, capacity data, and strategic importance ratings that align with your business objectives.

BiztechCS will configure automated tracking for key metrics: delivery performance, quality scores, responsiveness, and cost trends, creating a comprehensive supplier intelligence system.

BiztechCS will develop custom dashboards that provide real-time insights into supplier performance, enabling proactive relationship management that transforms vendors into strategic partners.

Consider how this plays out in practice:

Your analytics dashboard shows that Supplier A’s delivery performance has declined from 95% to 87% over the past month. Instead of waiting for a stockout, you reach out proactively to understand their challenges and adjust your procurement strategy accordingly.

When evaluating a new supplier, you have comprehensive data on how similar suppliers have performed, enabling more informed decisions about onboarding and risk management.

In our strategic consultations, we always probe deeper: “How do you currently measure supplier performance? Are your supplier relationships based on historical assumptions or current data?” The answers reveal opportunities for transformation that many manufacturers haven’t considered.

BiztechCS has developed (and will apply) a comprehensive approach to supplier relationship management that balances hard metrics (delivery, quality, cost) with soft factors (communication, flexibility, innovation support). This holistic methodology strengthens partnerships while maintaining accountability, creating win-win scenarios that drive long-term success.

The results speak for themselves.

According to PwC’s Global Digital Procurement Survey 2024, 65% of procurement departments now name cost control as their top strategic priority, while an impressive 94% have adopted source-to-pay (S2P) systems to boost efficiency and transparency (source).

But the transformation goes beyond numbers,

Odoo Consultant Tip: Never roll out too many modules at once. Start with Procurement + Inventory, stabilize, then expand. This phased approach prevents overwhelm and ensures higher adoption rates across teams.

Here’s what often surprises manufacturers: the benefits compound over time. Month 1 might deliver basic visibility and reduced manual work. Month 6 brings predictive insights and proactive decision-making. Month 12 often reveals strategic advantages they never anticipated—like the ability to respond quickly to market opportunities or weather supply chain disruptions that cripple competitors.

When we begin our assessment process, we start with a fundamental question: “If you could eliminate just one procurement-related headache from your daily operations, what would it be? How much time and stress would that save your team?” This question often unlocks the core issues that need immediate attention. And leadership teams usually add, “If that single headache disappeared, what could we finally focus on instead?” The answer is often growth: scaling operations, investing in R&D, or enhancing customer experience. That’s the ripple effect Odoo creates—solving one bottleneck unlocks entirely new opportunities.

The journey to streamlined supply chain management with Odoo doesn’t require a complete operational overhaul overnight. Here’s how successful UAE manufacturers typically approach the transformation:

At BiztechCS, we’ve learned that manufacturers who take a phased approach achieve better user adoption and see measurable improvements at each stage, building momentum for the complete transformation. This is why we’ve structured our methodology around progressive implementation rather than overwhelming system overhauls.

Manufacturing in the UAE is evolving rapidly, and supply chain excellence is becoming a key differentiator. The manufacturers who thrive in the coming years will be those who move beyond reactive procurement to strategic, data-driven supply chain management.

If you’re ready to explore how automated procurement with Odoo could transform your operations, we’re here to help you navigate that journey. Every manufacturer’s needs are unique, and the most effective transformations are tailored to your specific challenges, goals, and operational context.

The question isn’t whether to modernize your procurement and supply chain operations—it’s how quickly you can gain the competitive advantages that come with integrated, intelligent systems.

Curious how Odoo-powered procurement can give your manufacturing operations a competitive edge? BiztechCS helps UAE manufacturers achieve transformation with minimal disruption and maximum impact.

All product and company names are trademarks™, registered® or copyright© trademarks of their respective holders. Use of them does not imply any affiliation with or endorsement by them.

Artificial Intelligence (AI)

285

By Nandeep Barochiya

Odoo

332

By Uttam Jain

Artificial Intelligence (AI)

609

By Nandeep Barochiya