Optimizing Small Retail with an AI Inventory Management System

10 min read

10 min read

Two years ago, a mid-sized automotive plant in Germany cut operational costs by 20% and increased output by 15%—all after integrating artificial intelligence in manufacturing (source). It was no accident, whatever it may appear to be. It marks a transition from machines that follow instructions to those that can learn, adapt, and self-optimize.

Typical assembly lines that were rigid and linear in nature are now reacting to the data in real time. The process never happened overnight. It continued with an increase in the desire to be competitive, reduce waste, and maximize output.

Behind this transformation are innovations driven by strategic partnerships and expert AI development service providers that help companies implement intelligent systems tailored to their unique production needs.

So, this blog proposes how artificial intelligence in manufacturing is building smarter, faster, and efficient factories.

We shall also move on to some real examples of AI in manufacturing and how companies can ride the wave profitably, without disturbing their traditional production system in an AI manner.

Artificial intelligence manufacturing is the application of data-driven systems to ensure better operations for factories. These systems learn from patterns, come to decisions, and optimize processes on their own without being reprogrammed each time.

Machine learning predicts equipment failures and minimizes machine downtimes. Computer vision reduces the time required for quality checks while increasing precision beyond human capability. Robotics carries out operations very fast and with precision.

Data analytics tie them all together to provide decision makers with clear and actionable insights. These components enable connected and responsive operations that meet the demands of modern industries.

As a result, AI in manufacturing is playing a key role in helping the industry align with Industry 4.0 objectives, from efficiency to adaptability within the production system in AI-supported environments.

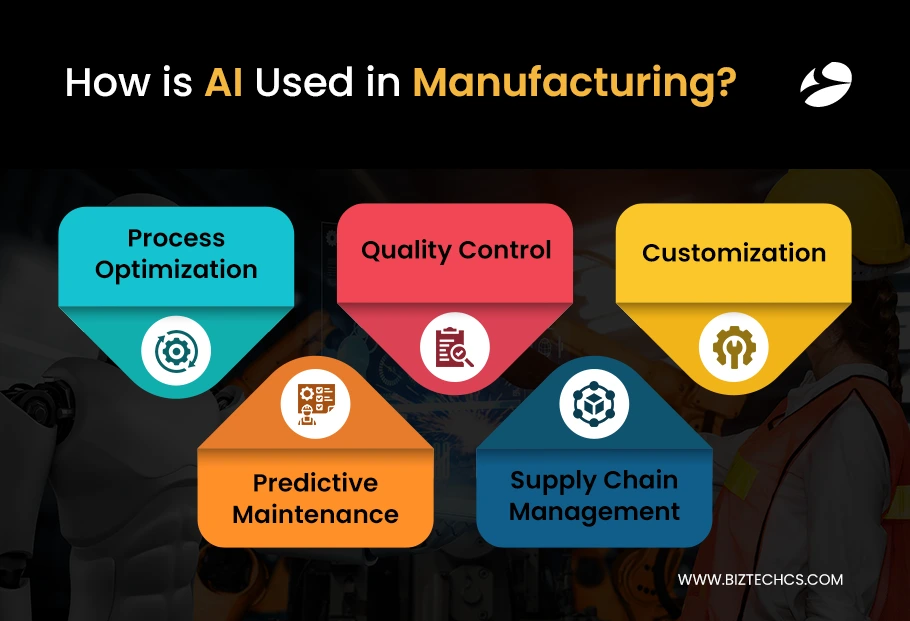

AI tracks every movement in the production line in real time. It spots a delay, an idle machine, or a bottleneck the moment it happens. Tiny adjustments to the flow can be made instantly without interrupting operations.

These changes are to cut waste and allow production to flow unimpeded. With time, the system learns and improves after every shift.

Sensors feed live data from machines into learning models that pick up signs of wear before a failure occurs. They set warnings when something is about to break down, not after it.

This reduces downtime, avoids random maintenance, and helps to protect the lifespan of expensive equipment.

In quality control, AI uses various cameras and vision systems to scan each unit on the line. It quickly flags defects faster than manual checking.

Also, minor defects invisible to human eyes are caught. This increases product cohesiveness and decreases returns. Thus, the inspection is faster and much more reliable.

AI studies past trends, current orders, and other external factors such as weather or fuel prices. Thus, it will be able to predict demand with greater confidence, accordingly deciding on changing procurement, storage, and delivery schedules to minimize delays and overstocking. Planning is done far out and not just reactive.

AI evaluates customer preferences and behavior data. Based on these data, it tweaks the production setup to manufacture customized items on a large scale. This creates a variety of other factors that could slow down the line.

Orders are filled faster, and inventory stays low. There is no longer any compromise between personalization and efficiency.

AI monitors each part of the line’s performance. Whenever something slows down, the system reacts. Either resources are shifted, or the speed is adjusted, all in the bid to keep work flowing.

This reduces delays and keeps machines running without interruptions for longer periods. These little gains then amount to rapid production outputs with time.

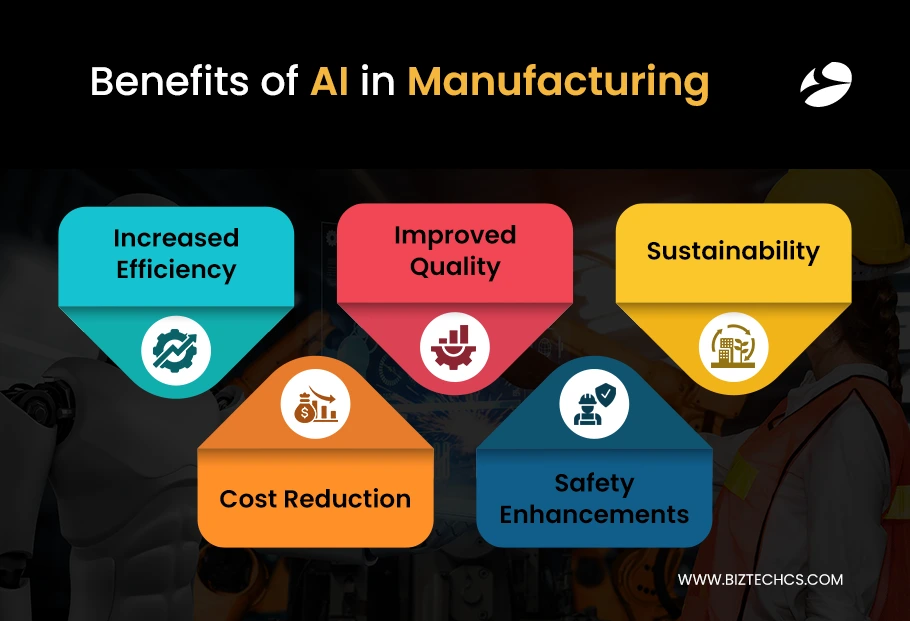

There is automation to replace the manual activities that require human resources. Energy consumption is reduced by AI systems that operate machinery depending on present needs.

This cuts down on overproduction and stoppage time. Each step seems trivial on its own, but together, they build an impressive picture of cost reduction, with an ROI in mere months.

AI systems examine every detail concerning the product at the time it is actually being made, recognizing defects when they appear and attempting to correct any problems before the products leave the floor.

This level of quality control reduces the number of defective goods produced. It also ensures clients get the same product every time, making consistency a part of the process rather than a mere exception.

The AI continually monitors the behavior of the machine and worker movement. If any activity appears hazardous, it sends a warning or shuts down the process, thus preventing injuries caused by malfunction or error. Workers are kept from harm; safety becomes embedded in the system.

AI observes material intake and adjusts processes to minimize wastage. It acts against overproduction and energy consumption where possible. Based on real-time information, water, heating, and electricity are optimized. Fewer resources are wasted, and emissions also recede. This is one step toward greener manufacturing.

A company running multiple water treatment plants suffered inconsistent data collection, leading to late decisions and a lack of real-time visibility at sites. A centralized cloud platform was created, integrated with real-time monitoring systems and SCADA interfaces.

The remote control and automated data treatment capabilities helped reduce manual intervention, hence faster issue detection, better regulatory compliance, and reduction in plant downtime.

A coated fabric company struggled with measuring raw material consumption, tracking production output, and ensuring quality control across batches. An ERP system was customized to link production, inventory, and quality control into a streamlined process.

AI-driven reporting and data validation were used to identify inconsistencies at the early stages of the production cycle. The company achieved tighter quality control, lower waste, and faster orders with higher accuracy.

A chemical distributor faced inefficiencies in field team management, particularly in scheduling, routing, and visit tracking to customer sites. A mobile solution was created with intelligent scheduling, GPS-based tracking, and real-time reporting.

AI-driven geofencing and route optimization ensured field agents remained on schedule and traveled farther with less effort. This resulted in improved service coverage, enhanced employee productivity, and increased customer satisfaction.

A business dealing in custom print products, supplying printed flags, was experiencing increasingly complex orders and product variant/customer personalization challenges.

A fresh digital interface was established that connected in real time directly to production cycles and enabled the forecasting of demand through AI-helped analysis of historical sales figures.

Automated decision-making rules secured that personalized orders were processed appropriately without delay.

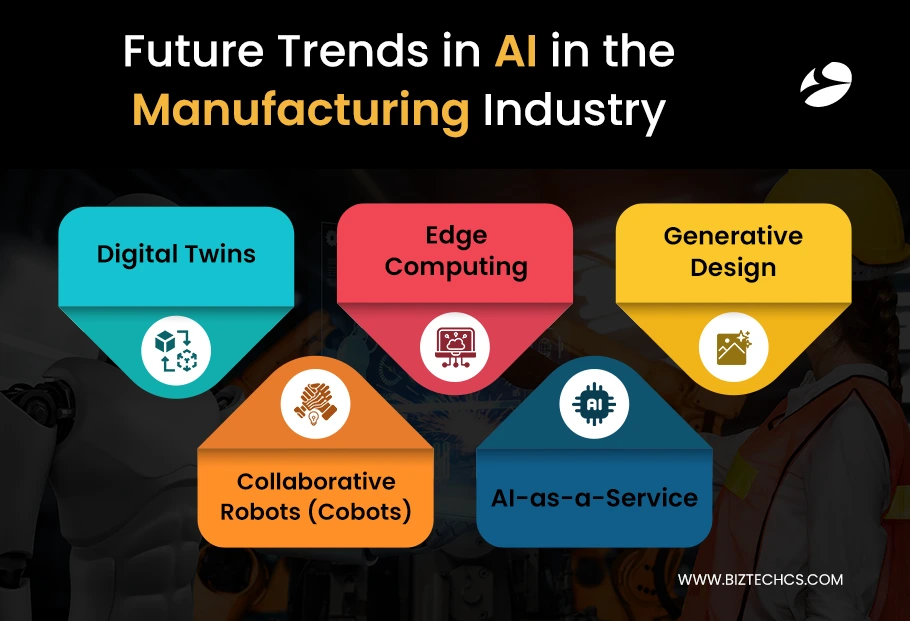

Companies are now using digital twins to make real-time decisions without halting production. These are computer simulations of machines, processes, or even factories. AI updates these twins with real-time data from the shop floor.

This enables teams to try out changes without risking them. Engineers can test performance, identify failures, or rework workflows—all virtually. It saves time and money and avoids trial-and-error on physical installations. Digital twins will have an increasing role as systems become more interconnected.

Key Highlights:

Cobots are programmed to work in tandem with people, not for them. They adapt in real time to human presence and motion. Cobots perform repetitive, hazardous, or physically demanding tasks, leaving people to do higher-value tasks.

Cobots learn fast and can be rolled out without reconfiguring the entire floor. They also minimize strain injuries and enhance task accuracy. Their application is increasing as demand for flexible production increases.

Quick View:

Factories produce an enormous amount of data per second. Edge computing processes the data in real time on-site where it is produced, reducing the latency of sending it to off-site servers. AI systems react quicker, in many cases, in real time without internet latency.

It enhances equipment management, product quality, and problem response times. It also keeps sensitive information secure by storing it locally. As systems expand, edge configurations become central to real-time decision-making.

At a Glance:

Smaller and medium-sized manufacturers tend to be deterred by AI adoption because of the cost. AI-as-a-Service provides a realistic alternative with pay-as-you-go solutions. It provides access to AI capabilities such as forecasting, visual inspection, and predictive maintenance.

Deep in-house expertise is not required. Providers maintain and update these services. Teams only need to pay for what they consume. This solution makes AI viable for more businesses.

Implementation Insights:

AI is empowering engineers to break free from conventional design constraints. Given a set of specifications such as weight, strength, or material, the system produces several alternative designs. It provides suggestions of shapes and structures that aren’t immediately apparent to humans.

The designs are iterated and optimized through data. This reduces development times and enhances product performance. It’s a move from hand-crafting to directing smart systems.

Generative design is being implemented in early-phase product planning throughout the industry.

Core Insights:

AI models are based on huge amounts of clean, structured data. Most manufacturers still work with old records or broken inputs. When this data is input into a system, the results can be deceptive.

This hinders progress and introduces risk into automation plans. Enhancing data quality is usually the first—and most neglected—step to AI success.

The majority of factories operate on systems developed years ago. Legacy platforms don’t necessarily integrate easily with AI solutions.

Manual workarounds and custom connectors are frequently required. This introduces complexity and slows things down. Time, planning, and support from both operations and IT are necessary for seamless integration.

Implementing AI involves a high initial cost, including software, hardware, and professional personnel. For others, the investment may take some time to materialize.

Value over the long term exists, but initial statistics may be troubling. Budget realignment becomes paramount prior to undertaking any large-scale implementation.

AI technologies don’t deploy themselves—they require trained staff. Most plants lack personnel with experience in data science or AI technologies.

Reskilling existing employees takes months, sometimes years. Recruiting fresh talent strains the budget. Plugging this hole is now as important as the technology itself.

As factories become intelligent, they become vulnerable. AI systems rely on continuous data flow, which needs to be secured. A single incident can stop production or reveal sensitive information.

Old security protocols may not cover new AI networks. To remain safe, update tools and protocols simultaneously.

Artificial intelligence (AI) in manufacturing is revolutionizing the way companies manage efficiency, quality, and decision-making. Through AI, manufacturers can automate processes, forecast maintenance requirements, and maintain consistency in quality control. These innovations make operations more efficient, minimize waste, and maximize overall productivity.

BiztechCS possesses extensive knowledge of implementing AI solutions that enable companies to cope with the complexities of contemporary manufacturing. Our team specializes in installing AI-driven systems that integrate with current infrastructure, offering customized solutions to each client’s requirements. Whether you’re exploring smart robotics, predictive analytics, or a modular manufacturing solution that adapts with your growing production needs, our AI expertise ensures seamless and scalable integration.

We use AI in manufacturing to create quantifiable outcomes, from predictive analytics to automated robotics. If you’re ready to discover AI integration, the time is now to determine your readiness and explore how these solutions can serve your company.

Let’s connect and see how BiztechCS can steer your AI journey and streamline your production system using AI-driven methods.

Artificial Intelligence (AI)

360

By Nandeep Barochiya

Odoo

428

By Uttam Jain

Artificial Intelligence (AI)

755

By Nandeep Barochiya