2733

How to Automate Preventive Maintenance, Decrease Equipment Downtime, and Improve Asset Lifespan Using Odoo ERP?

5 min read

2733

5 min read

Production downtime can cost manufacturers as much as $260,000 per hour, according to Aberdeen Research (source). Preventive equipment failure derails workflows, imposes strains on operational budgets, and decreases plant efficiency.

Reactive maintenance remains common in some plants, where action is only taken once the equipment fails. This leads to extended downtime and puts maintenance crews into crisis mode.

Ultimately, inconsistent care causes machines to deteriorate more quickly, reducing their lifespan and increasing replacement costs.

Odoo preventive maintenance transforms this challenge into a benefit by shifting maintenance from a reactive to a planned approach. From automatic scheduling to smart alerts, factory preventive maintenance reduces unexpected shutdowns and improves overall equipment reliability.

The system operates in real-time, enabling quicker decision-making and smarter maintenance. As a result, companies using Odoo’s equipment maintenance software experience fewer downtime incidents and better monitoring of machine health. Regular maintenance helps increase asset lifespan, reduces costs, and ensures a smoother production process.

| Challenges | Consequences |

|---|---|

| Manual tracking of maintenance logs and schedules. | Frequent breakdowns and costly downtime. |

| Uncoordinated maintenance tasks across teams. | Inconsistent performance from machines. |

| Lack of real-time asset health visibility. | Reduced ROI on high-value equipment. |

| Difficulty in predicting failures without a preventive maintenance system. | Increased emergency repairs and unplanned service interruptions. |

| Limited integration with ERP maintenance scheduling. | Delays in procurement and resource planning for maintenance activities. |

| Use of outdated methods instead of modern equipment maintenance software. | Inability to capture and analyze maintenance data for continuous improvement. |

| Poor documentation and version control for standard operating procedures. | Loss of tribal knowledge and variability in maintenance quality. |

| Lack of accountability and unclear task ownership in maintenance teams. | Missed or duplicated maintenance efforts. |

| Infrequent inspections or audits of equipment. | Gradual wear-and-tear going unnoticed until major issues arise. |

| No automated alerts or notifications for upcoming maintenance activities. | Failure to service equipment on time, risking performance and safety issues. |

| Insufficient technician training on new systems and protocols. | Increased human error and prolonged repair times. |

| Fragmented communication between operations and maintenance departments. | Misaligned priorities, resulting in delayed or skipped maintenance. |

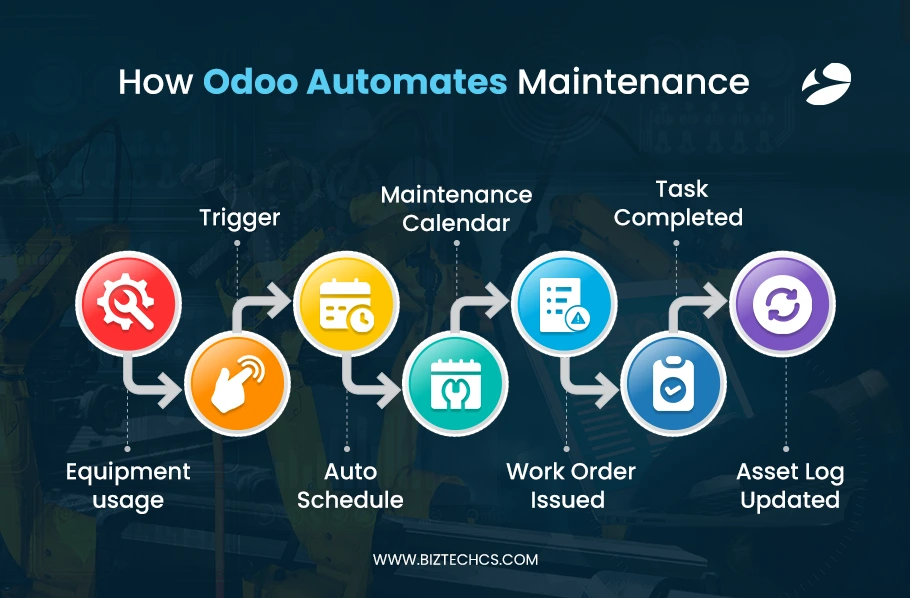

Automated Scheduling:

Odoo ERP software development provides an automatic scheduling system for maintenance work. It allows an enterprise to configure the maintenance period either based on usage hours or a fixed interval.

Such automation in the system ensures the correct timing for maintenance activities, reducing the chances of equipment experiencing unexpected breakdowns. Odoo also efficiently generates work orders for inspections and servicing, thereby reducing human effort, preventing missed inspections, and turning routine maintenance tasks into a smooth process.

Maintenance Calendar and Notifications:

Odoo offers a maintenance calendar that provides a graphical display of upcoming maintenance events. This calendar view helps managers effectively track and plan maintenance activities.

Notifications are sent to technicians and managers about tasks due for service, ensuring everyone works in unison. This way, nothing is missed from the list, and tasks are completed within the stipulated time, increasing productivity and minimizing downtime losses.

Real-time Equipment Tracking:

Using the equipment tracking feature of Odoo ERP, businesses can monitor the health status of their equipment in real-time through a single interface. This feature enables managers to gain insights into the condition of their assets and make informed decisions about maintenance requirements in a timely manner.

In addition, all maintenance log histories are accessible directly from the asset profile. This provides detailed information on past repairs and inspections, making it easier to analyze trends and predict future failures.

Integration with Inventory and MRP:

Odoo integration services preventive maintenance is integrated with the inventory and material requirements planning (MRP) modules. This integration automatically checks the availability of spare parts to prevent delays caused by unavailable components.

Moreover, Odoo enables the planning of maintenance activities around production cycles, ensuring that production is not hindered by maintenance, thereby improving efficiency and reducing downtime.

To reduce manual intervention and eliminate errors in scheduling, Odoo’s maintenance automation tools must be implemented to ensure that systems conduct scheduled preventive maintenance without fail.

The Odoo maintenance module is a data-driven and dependable method for managing assets, extending equipment’s lifespan, and optimizing overall performance.

In summary, Odoo ERP eliminates the hassle of preventive maintenance, enabling the company to achieve better asset performance, reduced downtime, and lower maintenance costs.

With automation of key activities and real-time insights, the company ensures that its assets are always in top shape and are managed efficiently. This is the essence of a solid preventive maintenance system, bringing long-term value and operational excellence.

Downtime Reduction

Unexpected stoppages result in losses and disrupt operations, so a proactive approach must be taken in advance to prevent such situations. Under the Odoo ERP for manufacturing, the premise of scheduling preventive maintenance in advance is established, allowing machine problems to be identified before they develop into major breakdowns.

In turn, unplanned downtime can be prevented. Once issues are identified early, companies can maintain smooth workflows and avoid operational stoppages from cascading into a halt.

Asset Longevity

Through regular maintenance, equipment continues to perform at peak efficiency, significantly enhancing the service life of an asset. Odoo ERP enables the efficient tracking of maintenance activities, ensuring that assets are maintained in the best possible condition.

When repairs and inspections are conducted on time, wear and tear are minimized, preventing premature failures. Machinery that receives proper care and maintenance remains serviceable for a longer time.

This approach pays off by delaying high-cost replacements, saving capital, and ensuring that current assets continue to provide value. Regular maintenance helps increase asset lifespan and ensures that the investment made in them is well worth it.

Resource Optimization

Better planning and control of tasks assist in the optimal utilization of resources. The ERP system from Odoo helps ensure that tasks are assigned to the right people who are skilled and available to carry them out at the right time.

This improves productivity by avoiding idle workers and ensuring that maintenance work is carried out without unnecessary delays. Thanks to accurate scheduling of resources, businesses avoid overburdening teams or wasting their workforce, as maintenance is always completed within the stipulated time and with precision.

Cost Savings

Reduced emergency work and improved procurement practices lead to cost savings. Odoo ERP simplifies the process of planning regular maintenance, minimizing the occurrence of costly emergency situations.

Through inventory tracking and orders, companies can effectively manage the procurement of spare parts, preventing both excess orders and delays. This practice of planned maintenance helps decrease equipment downtime. It saves companies money on repairs, thereby reducing the impact of downtime on daily business operations and resulting in long-term savings.

Customizable Maintenance Workflows

Odoo ERP for manufacturing enables the creation of customized maintenance workflows, making it an ideal solution for companies with unique machinery requirements. Each company can determine its own maintenance cycle to suit the equipment’s individual life cycle, ensuring that action is triggered at the optimal time.

Odoo ERP customization enables manufacturers to maintain efficiency and prevent downtime by addressing the distinct requirements of their equipment, which vary from one company to another.

Modular and Scalable

As businesses expand, their maintenance needs also increase. Odoo ERP is scalable, making it perfect for businesses that start small and grow over time. Manufacturers can start with a basic preventive maintenance feature and add more advanced features step by step as their operations evolve through the modular Odoo ERP modules.

This modularity makes Odoo a long-term solution that can keep pace with changing business requirements without requiring the replacement of the entire system.

User-Friendly Interface

Ease of use is one of the key reasons why manufacturers trust Odoo preventive maintenance. The platform features user-friendly forms and visually guided dashboards, making it simple for users to maintain and track maintenance schedules.

The easy-to-understand, simple-to-read interfaces allow teams to access vital information quickly, track asset conditions, and schedule maintenance tasks effortlessly. The user-friendly design saves training time and enhances system adoption.

Fully Integrated System

Odoo ERP is not just maintenance software; it is an integrated system that communicates with procurement, inventory management, and manufacturing resource planning (MRP). Smooth integration ensures effective operations and firmly ties the maintenance processes to overall business functions.

For example, when an asset requires maintenance, the system automatically triggers a procurement order for replacement items, all done without manual intervention.

Odoo ERP goes beyond being just a maintenance tool—it’s a fully integrated system that connects procurement, inventory management, and manufacturing resource planning (MRP) into one cohesive workflow. This level of integration ensures maintenance is no longer a siloed function but a strategic part of the entire production process.

Take this for example: when an asset requires maintenance, Odoo ERP Implementation can automatically trigger a procurement request for the replacement parts—no delays, no manual intervention. This automation extends throughout the manufacturing ecosystem, reducing downtime and ensuring your teams stay focused on production efficiency, not firefighting operational issues.

For decision-makers, Odoo puts control back in your hands. With routine workflows running in the background, leadership can shift their attention from operational hurdles to strategic growth—scaling smarter, not harder.

Want to unlock smarter manufacturing?

Discover how Odoo streamlines quality and maintenance while giving you the bandwidth to lead with strategy. Let’s explore how Odoo can transform your operations—book a personalized demo or connect with our team today.

All product and company names are trademarks™, registered® or copyright© trademarks of their respective holders. Use of them does not imply any affiliation with or endorsement by them.

Odoo

52

By Uttam Jain

Odoo

42

By Uttam Jain

Artificial Intelligence (AI)

99

By Nandeep Barochiya