2246

How to Simplify Product Lifecycle Management, Accelerate Product Approvals, and Ensure Regulatory Compliance with Odoo ERP?

5 min read

2246

5 min read

Managing a product’s lifecycle, especially in high-tech industries, demands speed, accuracy, and full traceability. Many data center teams and network admins struggle to keep up with shifting regulatory demands and approval workflows.

Odoo ERP provides a streamlined approach to managing product lifecycles, eliminating complexity. Its centralized system can reduce product development time by up to 20%, according to a study by SoftwareSuggest.

Gamers and hardware teams benefit from fewer version mismatches and tighter configuration management. Built-in compliance tracking cuts regulatory delays by 30%, helping teams avoid costly launch bottlenecks.

Product approvals move faster with automated checkpoints and digital documentation. This blog examines how odoo erp development streamlines PLM, accelerates approvals, and ensures compliance remains on track from start to finish.

The Hidden Mathematics of Product Development Chaos

When it comes to numbers, the disturbing impacts of disconnected product development processes come to the forefront.

Companies without integrated PLM systems experience 40% longer time-to-market cycles, while manufacturing companies that have ERP systems integrated into their core achieve a 66% efficiency in process standardization, compared to 31% for those without any form of integration (source). However, these numbers only represent visible inefficiencies.

The actual damage occurs beneath the surface in the form of invisible friction: design teams working from outdated BOMs, QA teams discovering nonconformities after production has commenced, or worse, regulatory systems faltering and turning a minor documentation error into a six-figure payment for an FDA infraction.

Consider MedTech Innovations, an aspiring cardiac device manufacturer on the verge of closure after a failed FDA audit, where the “comprehensive” quality management system was found to be nothing more than a series of Excel spreadsheets and email attachments.

Critical design changes were essentially undocumented, version control was non-existent, and retroactive compliance traceability could not be established.

In such cases, implementing regulatory compliance software could help mitigate these risks and ensure streamlined processes from design to production.

Converting a compliance liability into a competitive advantage is at the heart of product development.

Modern product life-cycle management (PLM) goes beyond simple inventory tracking or document storage. In today’s highly competitive environment, where the global PLM market is forecasted to reach $81.01 billion by 2034, growing at a CAGR of 9.24%, PLM serves as the digital nervous system connecting engineering excellence with operational efficiency. Source: Precedence Research

BiztechCS recognized this need and developed a specialized Odoo PLM module implementation methodology, tailored to the complex demands of regulated industries. This methodology addresses the intersection of product complexity and regulatory intensity.

Unlike general document management systems, our approach understands that every product decision impacts design, manufacturing, QA, and regulatory compliance.

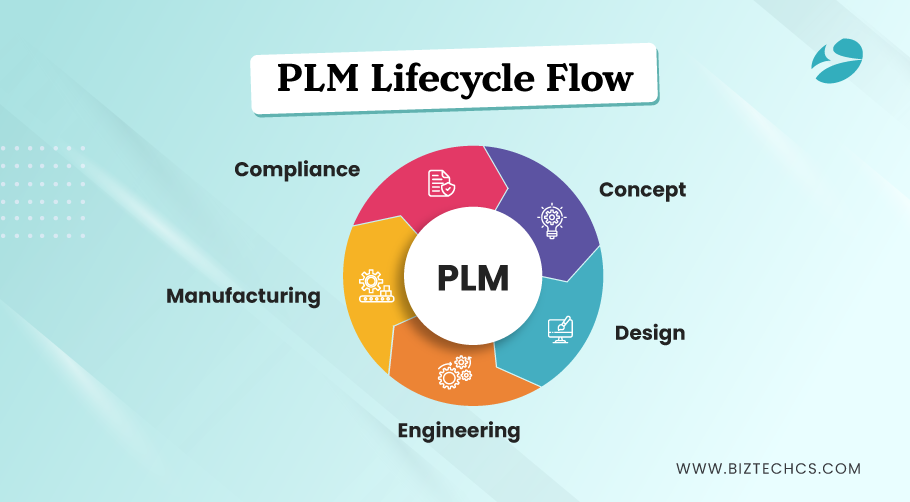

Odoo PLM Advantage: Intelligence at Every Stage of Development

In classical product development scenarios, lifecycle management is often treated simply as documentation. It encompasses the creation of designs, the development of products, and ultimately, the compliance process.

odoo erp software development for manufacturing addresses this by integrating lifecycle intelligence directly into its development architecture.

Every design decision requires intelligent validations: Have regulatory requirements been captured? Have risk assessments been made? Has change management been effectively implemented?

Instead of just tracking product development, the system manages it. Whenever design engineers initiate a change, the system automatically routes it for approval to stakeholders while retaining all audit trails.

If QA identifies any issue, the change management workflow automatically activates, recording and verifying the corrections until they are fully implemented.

💡 BiztechCS Implementation Philosophy: “We don’t just configure PLM systems; we architect development ecosystems that transform regulatory compliance from a constraint into a competitive advantage. Every workflow, every approval gate, and every documentation requirement becomes an enabler rather than an obstacle.”

Strategic Questions Every Product Development Leader Must Answer:

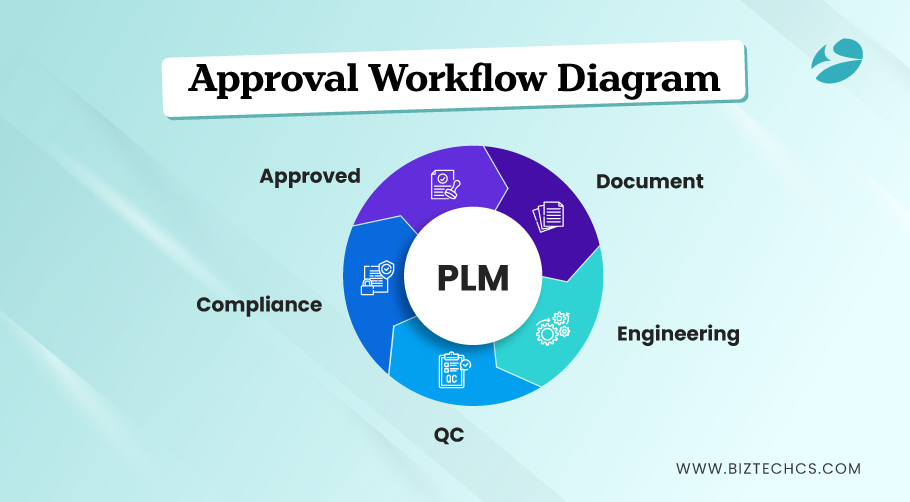

Can your current system prevent the release of products with incomplete compliance documentation? If your answer involves manual checking or departmental vigilance, you’re operating with systemic vulnerability. Advanced product approval workflow software creates automated safeguards that make compliance violations technically impossible.

The system won’t allow product release until all regulatory requirements are satisfied, risk assessments are completed, and approval workflows are properly executed. This isn’t just error prevention; it’s organizational risk elimination through systematic enforcement.

Do you have real-time information about the latest developments on all concurrent projects? If you have various product development initiatives managed through separate tracking systems or consolidated spreadsheets, you are working without strategic intelligence.

Full PLM provides dashboard visibility into development status, resource allocation, and approval bottlenecks across the product portfolio.

Early warnings and automatic escalations occur in the system whenever regulatory deadlines loom or critical milestones are missed, transforming management into a proactive process rather than a reactive one.

How fast does your team generate comprehensive product documentation for regulatory submissions? Instant report generation with full traceability of development is the accepted gold standard. If your process takes more than 30 minutes to generate complete regulatory documentation, you have put yourself at a competitive disadvantage.

Modern PLM maintains continuous submission readiness. Every design decision, test result, and approval step automatically feeds into regulatory reporting frameworks, which can generate FDA, ISO 13485, or other compliance documentation on demand.

Ready to turn chaos in product development into competitive advantages? Our PLM consultants have helped manufacturers in regulated industries reduce approval times by 50% and achieve 100% regulatory compliance. Let’s see how much transformation we can bring.

The first time Dr. Sarah Chen contacted BiztechCS, she was the VP of Product Development for VitalTech Medical Systems. Her team was managing seven medical device projects simultaneously using a combination of CAD systems, shared network drives, and email approval systems. While their technical expertise was exceptional, the operational infrastructure was fundamentally broken.

“We had brilliant engineers designing life-saving devices,” Dr. Chen remarked during our discovery session. “But we spent more time hunting for the latest design files than actually designing. Every FDA submission felt like an archaeological expedition through months of scattered documentation.”

Due to the tension between innovation capability and operational reality, BiztechCS recognized the need to develop a comprehensive PLM transformation methodology. Changes are not meant to replace existing systems overnight but are introduced through carefully phased steps that build operational momentum and preserve development continuity.

Phase 1: Digital Architecture Foundation

The transformation began with what we term ‘product DNA mapping,’ which is a comprehensive audit of the existing design processes, approval workflows, regulatory requirements, and cross-departmental coordination patterns.

This was not just systems analysis; it was organizational archaeology, digging for the deeply embedded patterns that either make or break product development.

Our team was embedded with the engineering, quality assurance, and regulatory groups at VitalTech for three weeks, mapping not only what they created but also how information flowed between departments, where bottlenecks arose, and how regulatory requirements translated into operational requirements.

We discovered that their cardiovascular device line required 47 different approval checkpoints, while their diagnostic equipment followed completely different protocols, a complexity that their existing systems couldn’t accommodate systematically.

🔧 BiztechCS Technical Excellence: “We don’t simply install PLM systems—we interpret your product development DNA. Each approval process, each compliance milestone, and each change management regimen is tuned to your unique regulatory environment and organizational culture.”

Phase 2: Pilot Implementation – Single Product Line Validation

Instead of undertaking an organization-wide transformation all at once, we chose VitalTech’s most intricate product family—their FDA Class II cardiac monitoring products—as our pilot implementation.

This product line managed the most stringent regulatory demands, the most complicated supply chain coordination, and the highest market visibility, making it the ultimate proving ground for our PLM configuration.

The pilot phase built three key capabilities:

Integrated Design-to-Documentation Workflows: All engineering changes automatically initiate proper approval sequences while providing total audit trails. Design engineers could not make changes without conducting risk assessments and obtaining stakeholder approvals, but the approval process became streamlined rather than cumbersome.

Real-time Compliance Status Visibility: Project managers were provided with dashboard visibility into regulatory preparedness throughout the entire development phase. Rather than finding gaps in compliance during preparation for submission, possible issues were identified and addressed during routine development workflows.

Cross-departmental Collaboration Intelligence: Seamless collaboration existed between engineering, quality assurance, regulatory affairs, and manufacturing groups within the system. When changes in design impacted manufacturing processes, automated notifications ensured all parties were alerted and engaged in the approval processes.

Strategic Implementation Questions for Development Leaders:

How do you ensure that engineering modifications don’t generate downstream manufacturing or compliance problems? This question highlights a significant weakness in conventional product development.

Engineering teams often focus on technical excellence, but design changes can have cascading effects on manufacturing processes, quality control procedures, and regulatory compliance.

Without linked systems, these issues may surface during production or regulatory review, when fixes are costly and time-consuming.

Best-in-class PLM system for manufacturers closes this gap with intelligent change management processes. When engineers suggest design changes, the system automatically reviews potential effects in manufacturing, quality, and compliance areas.

Impacted stakeholders receive automated alerts with context-relevant information, enabling them to make informed decisions before change execution. This is not communication enhancement—it’s predictive collaboration risk mitigation.

The most advanced PLM deployment is worthless if development teams can’t leverage it instinctively amidst the controlled chaos of parallel project management. This insight led us to emphasize what we term “seamless Odoo Integration services“—technology that supports rather than complicates development processes.

Version Control That Controls

In our deployment at VitalTech, we observed development teams at their worst—those last few months leading up to regulatory submission, when even the smallest design change can drastically impact approval timelines.

Classic version control systems often force teams to choose between development speed and accurate documentation. Our Odoo product management setup eliminates this false dichotomy.

Each design file change now automatically generates version tracking with complete change history documentation.

The system manages side-by-side development branches, encourages collaborative modification, and ensures that all stakeholders are working with the latest versions of the code. Most importantly, it prevents conflicting or unauthorized modifications, even under pressure.

BOM and Product Versioning Excellence

Arguably, the most revolutionary part of the VitalTech deployment was achieving smart BOM and product versioning throughout every stage of development.

Previously, when design teams changed component specifications, manufacturing teams continued using outdated BOMs for weeks, leading to quality issues and potential regulatory violations.

Now, any change to a BOM automatically propagates to all impacted systems. If component specifications change, procurement groups receive real-time alerts, manufacturing operations are notified of revisions, and quality control procedures are updated accordingly.

This feature transformed supply chain coordination from reactive to predictive, turning potential production delays into proactive optimization opportunities.

📊 Business Impact Intelligence: Recent industry analysis shows that companies using advanced PLM systems reduced product-related carbon emissions by an average of 15%, while realizing significant improvements in development efficiency and regulatory compliance rates (Source:).

Multi-Project Portfolio Intelligence

The most advanced feature in our Odoo PLM setup is its portfolio-level intelligence. Instead of managing separate projects individually, the system reviews resource allocation, timeline interdependencies, and compliance requirements across all concurrent development projects. This facilitates strategic optimization that was previously unfeasible.

For instance, when submission deadlines for several products are approaching, the system detects resource conflicts and automatically recommends optimization measures. When standard components are used across multiple projects, the system aligns specifications to maximize efficiency while preserving project autonomy.

Follow-up Development Strategy Questions:

Does your system today automatically detect resource conflicts across multiple simultaneous projects? This capability distinguishes tactical project management from strategic portfolio optimization.

While most development organizations are successful at managing individual projects, they struggle with managing resources and timelines at the portfolio level.

Conflicts arise when different projects compete for overlapping engineering resources or regulatory focus as deadlines converge.

Sophisticated PLM systems provide portfolio-wide intelligence that detects potential conflicts before they escalate into critical issues.

The system evaluates resource demands, timeline interdependencies, and regulatory deadlines for all active projects, providing early notice when conflicts are likely to arise. This enables proactive resource redistribution and timeline adjustments, rather than reactive crisis management.

Do your design changes automatically trigger corresponding stakeholder notifications and approval processes? Manual change management is both an efficiency bottleneck and a compliance risk.

When design changes need to be reviewed and approved by stakeholders, manual procedures introduce delays, communication gaps, and inconsistencies in documentation. In stressful situations, these procedures tend to be shortened or skipped, creating regulatory vulnerabilities.

Systematic change management automates processes to ensure accurate reviews and approvals, preventing bottlenecks.

The system directs change requests to the relevant stakeholders based on modification type and impact analysis, keeps full audit trails, and prevents implementation until the necessary approvals are obtained. This turns change management into a competitive advantage rather than an administrative hassle by ensuring systematic excellence.

Curious about how integrated PLM intelligence could transform your multi-project development operations? Our implementation specialists are currently working with 25+ manufacturers across regulated industries. Schedule a portfolio assessment to explore your optimization potential.

Compliance in contemporary manufacturing has evolved significantly. It’s no longer just about documentation requirements.

Modern FDA quality management system regulations (QMSR), ISO 13485 standards, and global harmonization regulations require end-to-end traceability, real-time risk management, and ongoing audit preparedness.

These capabilities can’t be achieved through paper-based or disparate digital solutions at scale.

The healthcare industry illustrates this transformation most strikingly. Healthcare PLM is growing at the highest rate, 11.1% CAGR, driven by stricter regulatory demands.

Organizations can no longer view compliance as just a downstream documentation process. Current regulatory systems now require compliance intelligence across the entire development life cycle (source).

A key improvement during the VitalTech transformation was their regulatory approach. Previously, preparing an FDA submission took months. It involved manual documentation assembly, cross-referencing multiple systems, and finding traceability gaps.

Dr. Chen’s team would halt development activities for “submission prep,” which impacted innovation momentum and their competitive stance.

Predictive Compliance: When Your PLM System Becomes Your Quality Assurance Director

With odoo erp implementation modules correctly set up for regulated manufacturing, compliance has shifted from episodic crisis to seamless automation.

Every development decision—from conceptual design to final production details—is automatically generated to create the necessary documentation structure for regulatory management.

The system offers end-to-end product-level traceability, linking design choices back to risk analysis, stakeholder sign-offs, and verification of regulatory requirements. When FDA inspectors conduct facility audits, VitalTech personnel can now produce comprehensive compliance records in minutes, rather than months.

💡 BiztechCS Regulatory Expertise: “We don’t just help manufacturers pass audits. We assist them in documenting operational excellence that exceeds regulatory demands. This makes them preferred partners to healthcare systems and creates a competitive edge through systematic quality leadership.”

The New FDA Reality: ISO 13485 Integration

The regulatory environment is undergoing unprecedented change. The FDA’s new Quality Management System Regulation (QMSR) is scheduled to take effect in February 2026 (Source:).

It mandates the use of ISO 13485 compliance standards for medical device manufacturers. This is the most significant regulatory update in decades, necessitating comprehensive PLM capabilities to support both current and future compliance requirements.

Organizations that adopt sophisticated PLM systems now will be well-positioned for this shift. Instead of scrambling for compliance by 2026, they can develop systematic capabilities that naturally support regulatory changes.

If new requirements emerge, their systems can adapt through configuration, avoiding costly redevelopment.

Strategic Compliance Questions for Manufacturing Leaders:

How will your existing development infrastructure transform to meet the FDA’s new ISO 13485 requirements by February 2026? This query addresses the most pressing regulatory challenge medical device manufacturers face.

The transition to QMSR necessitates a comprehensive reform of the quality management system, which extends far beyond document updates.

Organizations must demonstrate systematic risk management, continuous improvement processes, and full traceability throughout the product lifecycle.

Companies with integrated PLM systems already have much of the infrastructure in place for ISO 13485 compliance. Their development processes include risk assessment, automated approval workflows, and complete audit trails.

The change now lies in system configuration, not a complete process redesign. Organizations without integrated systems face costly and time-consuming compliance initiatives that detract from product development and market competitiveness.

Can your system today show end-to-end product lifecycle traceability for any product in 15 minutes? This capability test distinguishes integrated PLM systems from simple document stores.

Regulatory bodies are increasingly demanding immediate access to comprehensive product development histories, including design rationale, risk analysis, change management history, and validation records. Manual compilation of this data is no longer acceptable for serious regulatory compliance.

Sophisticated PLM systems ensure end-to-end traceability, enabling real-time creation of complete product histories.

When regulatory issues arise, compliance departments can demonstrate the entire development history in minutes, not days. This capability not only meets regulatory compliance but also proves operational excellence, which helps drive premium market positioning.

When evaluating PLM investment for manufacturing operations, many leaders focus primarily on system costs rather than the potential for strategic value creation.

This perspective often leads to suboptimal decision-making, comparing sophisticated manufacturing-grade ERP solutions against basic document management tools without considering the fundamental differences in business impact.

The True Cost of Disconnected Product Development

Recent industry analysis reveals that manufacturing productivity increased by 3.2% in 2023, with PLM solutions being a key contributor to this growth (Source:).

However, these aggregate improvements mask the dramatic differences between organizations with integrated systems and those operating with fragmented processes.

Consider VitalTech’s pre-implementation situation: six-month regulatory submission cycles represented nearly 40% of their total development timeline.

Factoring in opportunity costs, resource allocation inefficiencies, and competitive disadvantages from delayed market entry, the real impact approached 60% of their innovation potential.

From this perspective, their Odoo PLM investment paid for itself within the first regulatory cycle through timeline compression alone.

Strategic Value Creation Beyond Efficiency Improvement

The most successful manufacturing ERP implementations generate value through multiple channels that extend far beyond process optimization:

Innovation Acceleration Multipliers: Advanced PLM capabilities enable concurrent development processes that were previously impossible.

When design teams can work simultaneously on multiple product variants while maintaining comprehensive change control, development cycles compress dramatically while quality improves. VitalTech now develops three product variants in the time previously required for a single product.

Regulatory Advantage Positioning: Organizations with superior compliance capabilities often achieve preferred status with healthcare systems, insurance providers, and regulatory bodies. This positioning enables premium pricing, accelerated approval processes, and strategic odoo partnership opportunities that command significant market premiums.

Knowledge Capital Optimization: Perhaps most significantly, comprehensive PLM implementation transforms individual expertise into organizational intelligence.

When design rationale, problem-solving approaches, and optimization strategies are systematically captured and accessible, organizations develop compound competitive advantages that improve over time.

🔧 BiztechCS Value Architecture: “We don’t sell PLM software—we architect innovation ecosystems that transform regulatory compliance from operational constraint into competitive differentiation. Every workflow, every approval process, every documentation requirement becomes an enabler of superior market performance.”

Ready to quantify the strategic value potential for your manufacturing operations?

Our ROI modeling specialists can demonstrate specific value creation opportunities based on your current development profile. Request a comprehensive value assessment today.

The manufacturing landscape is undergoing transformation, driven by technological advances, regulatory changes, and increasing global competition. Understanding these macro trends is essential for leaders evaluating long-term strategic positioning.

The Cloud-Native Development Revolution

The global PLM market is shifting toward cloud-based solutions, reflecting fundamental changes in how organizations approach product development. Cloud-based PLM solutions are growing at a 10.5% CAGR as companies prioritize remote collaboration, automatic updates, and elastic scaling capabilities (Source:).

For manufacturing operations, cloud PLM offers several advantages: automatic regulatory compliance updates, seamless multi-location collaboration, and reduced IT infrastructure complexity.

BiztechCS’s cloud-first Odoo implementations enable manufacturing organizations to scale rapidly without proportional increases in system administration.

When VitalTech decided to establish development partnerships with suppliers in Germany and Taiwan, their cloud-based PLM system enabled immediate collaboration without the need for extensive system integration projects. International partners were operational within days rather than months.

Artificial Intelligence Integration in Product Development

Advanced PLM systems now incorporate AI-driven capabilities that turn routine development tasks into strategic advantages.

Predictive analytics for development timeline optimization, automated compliance checking, and intelligent design validation are becoming standard.

Our latest Odoo PLM configurations include machine learning algorithms that refine approval workflows based on project outcomes, regulatory feedback, and quality metrics.

The system continuously learns from each development cycle, optimizing future projects with accumulated intelligence.

Sustainability and Circular Economy Integration

Sustainability is increasingly integrated into product development rather than being an afterthought. Companies using innovative PLM systems have reduced carbon emissions by an average of 15% through systematic lifecycle analysis and optimization (Source:).

Advanced PLM platforms offer sustainability analytics that assess environmental performance throughout the product development process. This allows organizations to optimize for environmental impact, technical excellenChallence, and regulatory compliance.

Strategic Positioning Questions:

How will your existing development infrastructure support more sophisticated international regulatory demands? Global market entry requires support for multiple regulatory schemes simultaneously.

For example, medical devices must meet FDA specifications for the U.S., comply with CE marking for the European Union, and adhere to various national standards for worldwide distribution. Navigating these requirements with independent systems increases complexity and risk.

Advanced PLM technology offers integrated compliance management, enabling simultaneous support for multiple regulatory frameworks.

The system includes detailed documentation that meets international standards while ensuring effective development processes. This capability becomes crucial as markets globalize and regulatory harmonization develops.

Can your IT infrastructure accommodate AI-powered development, optimization and predictive analysis? Competitive advantage increasingly depends on the ability to leverage AI for development optimization, risk prediction, and quality enhancement.

Data infrastructure must be sophisticated, with integrated workflows and comprehensive information architecture to support AI capabilities.

Organizations with mature PLM systems have the necessary data infrastructure for AI integration. Their detailed development documentation, process-tracking transparency, and quality metrics provide a foundation for machine learning. Organizations without integrated systems lack the data quality and system integration required for effective AI implementation.

Are you positioned to demonstrate environmental stewardship through rigorous lifecycle analysis? Environmental considerations are no longer optional but mandatory.

Healthcare systems, government agencies, and business customers are increasingly basing purchasing decisions on the environmental performance and sustainability practices of suppliers.

Companies with robust PLM systems can demonstrate environmental stewardship through lifecycle analysis, carbon footprint monitoring, and the optimization of sustainable design. This ability provides a competitive edge as environmental demands rise and stakeholder expectations shift.

The transformation of manufacturing PLM requires more than just technical setup; it needs strategic change management, stakeholder alignment, and systematic value realization. BiztechCS’s proven implementation methodology ensures both technical success and organizational change.

Discovery Phase: Production DNA Analysis

Every successful PLM deployment begins with a deep understanding of existing development processes, rather than focusing solely on current pain points.

Our discovery process identifies workflow patterns, uncovers hidden inefficiencies, and reveals optimization opportunities that may not be immediately apparent.

During VitalTech’s discovery phase, we found that their regulatory approval process involved 12 manual review cycles, creating potential bottlenecks and compliance risks.

More importantly, we discovered that 45% of their development effort could be automated through proper PLM configuration.

Configuration Phase: Manufacturing Intelligence Architecture

Generic PLM configurations often hinder manufacturing processes because they don’t account for the complexity of regulated product development.

BiztechCS’s manufacturing-specific configuration templates come with pre-set workflows for design control, change management, risk analysis, and regulatory reporting.

Our approach integrates manufacturing intelligence directly into system workflows. This guide helps users follow best practices while minimizing errors and maintaining compliance, eliminating the need to memorize complex processes.

Validation Phase: Real-World Development Testing

Before full deployment, we validate all configurations against real development scenarios. This includes project management, handling emergency changes, generating regulatory submissions, and system integration testing.

💡 Implementation Philosophy: “We don’t go live until the system works flawlessly under the toughest conditions your development teams face, such as regulatory submission deadlines, not during quieter development phases.”

Optimization Phase: Sustained Excellence Enhancement

PLM implementation doesn’t end at go-live. It continues with ongoing optimization based on real-world experience and evolving regulatory needs. Our post-implementation support includes regular monthly performance reviews, quarterly optimization meetings, and annual strategic planning integration.

Planning a manufacturing PLM transformation? Our implementation experts are available for Q3 2025 projects. Reach out to discuss your transformation timeline.

A successful PLM deployment creates measurable improvements across several development areas. Monitoring these metrics helps manufacturing executives set realistic expectations and track the progress of transformation gains.

Development Velocity Measures

The most tangible and quantifiable effect is the improvement in the development cycle:

Quality and Compliance Improvement

In addition to development velocity, PLM transformation enhances systematic quality:

Strategic Capability Creation

Most importantly, end-to-end PLM implementation builds strategic capabilities that create new business opportunities:

🔍 BiztechCS Philosophy of Success: “We don’t declare an implementation successful until our clients achieve a measurable competitive advantage. This means monitoring business results, not just system functionality.”

Looking ahead to the next ten years of manufacturing innovation, several technology and regulatory trends will redefine the role of PLM systems in product development operations.

Integrated Innovation Ecosystems

The boundaries between internal development, supplier collaboration, and customer co-creation continue to blur. Next-generation PLM systems will integrate more seamlessly with partner systems, customer feedback platforms, and market intelligence services.

This integration will transform manufacturers from product creators into innovation orchestrators.

Predictive Development Analytics

New analytics capabilities will enable manufacturers to forecast development challenges, optimize resource utilization, and anticipate regulatory needs before they become roadblocks.

This shift from reactive to predictive management is a key change that enhances competitive advantage in manufacturing.

Autonomous Compliance Management

As compliance requirements become increasingly complex, PLM solutions will continue to adapt to evolving needs through ongoing development. This includes regulatory reporting, predictive compliance risk analysis, and quality management workflows that adapt to regulatory changes.

The Cohesiveness Advantage: Achieving Sustainable Innovation Excellence

The revitalization of VitalTech, from a regulatory crisis to competitive excellence, highlights the significant impact of well-executed manufacturing PLM.

However, their success was not solely due to technology—it was about recognizing that operational excellence enhances innovation capability in complex regulatory environments.

The best PLM implementations achieve “development coherence,” where technology systems are so integrated with innovation processes that they become invisible facilitators rather than operational barriers.

This occurs when all system elements—design management, compliance tracking, change control, and quality assurance—work together as part of a single innovation intelligence platform.

At VitalTech, this coherence enabled them to develop more products simultaneously, improve compliance levels, and expedite market entry.

Their engineers now spend 70% more time on real innovation, regulatory staff can prepare submissions in days instead of months, and project managers base decisions on predictive analytics rather than intuition.

💡 Final Strategic Observation: The most effective PLM transformations do more than address current development challenges—they build the innovation capacity needed for future market opportunities. This requires thinking beyond system selection to strategic innovation design.

Ready to Transform Your Product Development Operations?

The journey from development chaos to innovation excellence begins by understanding your unique transformation potential.

BiztechCS has guided over 150 manufacturing operations through successful PLM transformations across regulated industries, including medical devices, aerospace, automotive, and industrial equipment.

Our manufacturing PLM specialists are currently accepting consultations for Q3 2025 implementation projects.

Whether you’re managing two products or twenty, struggling with regulatory compliance, or seeking to accelerate innovation, we’re here to help you architect your transformation journey.

Don’t let disconnected processes limit your innovation potential. Your engineering brilliance, market opportunities, and competitive future deserve systematic excellence.

BiztechCS is a certified Odoo implementation partner, specializing in manufacturing PLM transformations across the UAE and GCC region. Our team combines deep ERP expertise with industry-specific knowledge to deliver implementations that create a measurable competitive advantage through innovation excellence.

All product and company names are trademarks™, registered® or copyright© trademarks of their respective holders. Use of them does not imply any affiliation with or endorsement by them.

Artificial Intelligence (AI)

33

By Nandeep Barochiya

Odoo

70

By Uttam Jain

Odoo

62

By Uttam Jain