How a Middle Eastern Factory Cut Material Costs by 15% While Boosting Efficiency?

5 min read

5 min read

At 7:20 AM, Ahmad’s phone rang—it was yet another supplier delay. He opened three spreadsheets to check material availability, only to find conflicting numbers. This wasn’t unusual. It happens almost every week.

For over fifteen years, the manufacturer had built a strong reputation for delivering quality products across the Gulf. But behind the scenes, their operations told a different story—disorganized, reactive, and heavily dependent on manual coordination.

Production planning was managed on a single system, inventory was tracked in various scattered spreadsheets, and purchasing utilized a completely separate tool. The warehouse team hunted for missing parts daily, while procurement spent mornings chasing suppliers.

As Ahmad explained it: “We make great products despite our systems—not because of them.” That reality became a critical risk when the COO declared, “We just landed our biggest contract. Fix this ASAP, or we’ll fail spectacularly.”

The challenges were clear. Machines sat idle because parts were somewhere, but not traceable. Rush orders consumed ninety minutes, eight people, and six different systems to process. Each missed delivery puts millions in contracts and customer trust at risk.

The COO asked the tough question: “How do we scale without breaking our systems—or our people?” The answer came through BiztechCS’s phased approach to transformation using Odoo ERP development and Odoo Manufacturing Resource Planning (MRP) — empowering teams with real-time visibility and connected processes.

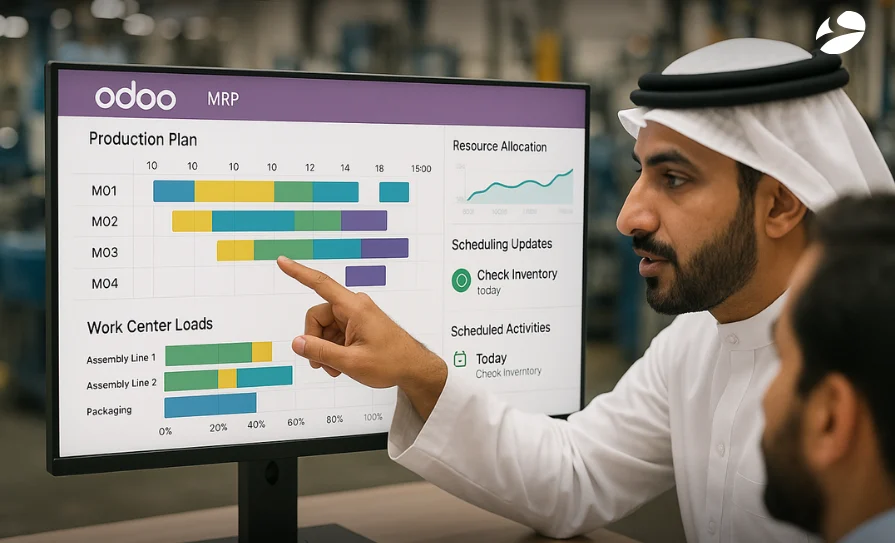

BiztechCS started with Ahmad’s biggest problem: production scheduling. It consumed his entire morning, and every decision stayed in his head.

For a week, the BiztechCS team observed Ahmad at work. His instincts were remarkable—one glance at an order and he understood timing, materials, and bottlenecks. But this knowledge never left his brain.

The consultants asked him directly: “What happens when you’re sick?”

“Everything stops,” he admitted.

Setting up Odoo production scheduling automation required understanding the difference between reality and assumptions. BiztechCS mapped every product, every process, and every constraint.

Initially, Ahmad resisted. “Software is too rigid. Every order is different here,” he argued.

BiztechCS spent three weeks configuring the system properly. Odoo MRP for resource allocation is tailored to real constraints, rather than imposing artificial limitations.

The breakthrough came when the team asked: “How much of your lead time is actual production versus waiting?” The answer shocked everyone—only 35% of the time was actually spent on manufacturing. The rest was coordination and delays.

The plant manager then asked: “If waiting consumes nearly two-thirds of our timeline, how do we capture that lost time?” With Odoo MRP, visibility into bottlenecks enabled them to significantly reduce idle waiting time, transforming delays into increased throughput. BiztechCS calculated that each idle day costs thousands in underutilized machinery and labor hours. By revealing those hidden costs, the urgency for change became undeniable.

When implementing Odoo MRP, avoid generic templates. Always configure workflows based on real-world production constraints, including capacity, shifts, and bottlenecks. Customizing scheduling rules ensures the system reflects reality, not assumptions.

Odoo Manufacturing Resource Planning (MRP) eliminates waiting. Most manufacturers build efficiently but struggle with timing decisions.

Six weeks later, Ahmad’s daily routine underwent a transformation. His dashboard highlighted exactly what needed attention. Morning crisis management was no longer required.

“It’s like having a GPS after driving blind for years,” Ahmad told his team.

Do you feel like your production team is running on instinct rather than clear direction? Real-time scheduling could be the difference between constant firefighting and confident growth.

The Gulf-based industrial leader knew their inventory on paper, but finding specific materials required detective work.

They operated three warehouses—the main facility plus two across town. Material movement followed availability and guesswork.

Yousef, the warehouse manager with thirty years of experience, could eventually find almost anything. But “eventually” was becoming too slow.

BiztechCS integrated Odoo’s Inventory module with the MRP system. Every movement was tracked automatically. Production runs updated stock levels instantly. Reordering happened based on real usage.

During setup, the BiztechCS team asked Yousef to trace one steel batch from delivery to finished product. The discussion lasted three hours.

The assessment revealed that materials were not missing, but often invisible in the system for days.

Integrated manufacturing processes with Odoo track the right things at the right time. Inventory data flows into production planning automatically. Decisions are made on facts, not assumptions.

After a month, Yousef’s first reaction was: “These numbers are actually correct?”

The CFO raised an important point: “Accurate numbers are great—but how quickly can we trust them enough to make financial decisions?” In addition, the COO added another perspective: “If we base investment or expansion decisions on inaccurate data, how much risk are we really carrying?”

That’s where Odoo ERP implementation made the difference—ensuring data accuracy, transparency, and real-time insights that empowered leadership to make confident, data-driven decisions.

BiztechCS showed that reliable real-time numbers not only reduced risk but also enabled more aggressive growth strategies. Within eight weeks, the manufacturer saw a 25% improvement in fulfillment rates. Confidence in real-time data became the foundation for faster, fact-based decisions.

Change happens gradually—then suddenly. Gaining clarity on current conditions alone often justifies the effort.

Hassan, the Supply Chain Manager, spent mornings creating purchase orders, afternoons chasing suppliers, and evenings trying to remember which vendors delivered on time.

During the review, BiztechCS asked Hassan directly: “How much time goes to routine orders versus strategic supplier management?”

His answer was painful: about 80% administrative tasks and only 20% strategic thinking.

The COO then asked: “If Hassan gains back that 60% of his time, how does that shift procurement’s role in our growth?” The answer was clear—procurement could become a driver of profitability.

The finance head followed with another challenge: “And if procurement becomes more strategic, how soon can we expect measurable savings to reflect in the bottom line?”

Within two procurement cycles, savings began showing up in reduced material costs and stronger supplier terms. With automation handling repetitive tasks, Hassan focused on building supplier partnerships, negotiating volume discounts, and enhancing reliability.

Odoo for procurement automation completely reversed that ratio. The system generated purchase orders automatically, tracked supplier performance, compared pricing, and calculated optimal order quantities.

Hassan’s role transformed overnight. Instead of focusing on paperwork, he concentrated on sourcing better suppliers, negotiating discounts, and cultivating valuable relationships.

The system handled routine tasks, including automatic reordering at predetermined levels, supplier scorecards based on performance, and approval workflows to ensure financial controls.

It also predicted material needs three weeks in advance. This gave Hassan time to negotiate better prices and secure backup suppliers for critical components.

Odoo Consultant Tip: Leverage Odoo’s vendor price lists and reordering rules together. This not only ensures timely procurement but also enables automated supplier comparison, helping procurement managers secure the most cost-effective contracts.

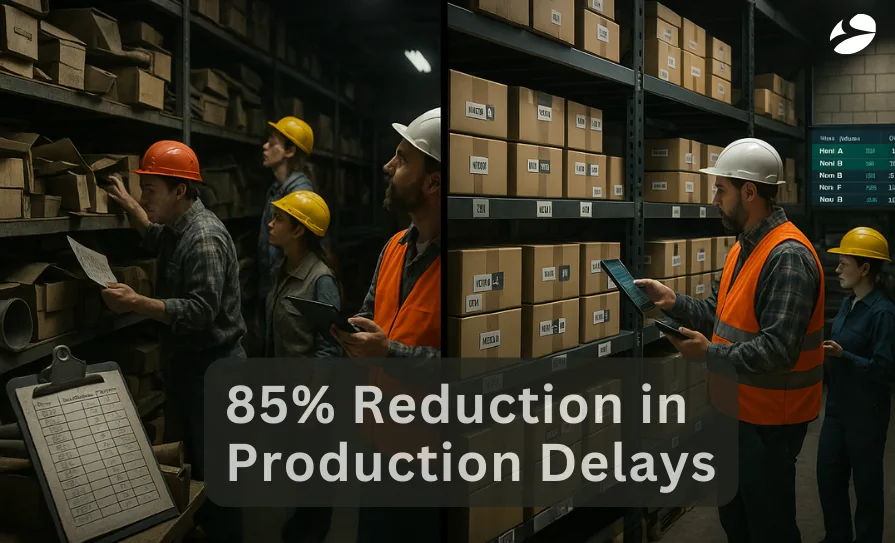

Three months after Odoo implementation, results were undeniable:

Speed increased: Production turnaround improved 20%. Scheduling aligned with material availability.

Costs decreased: Material expenses dropped 15% through improved inventory management and strategic procurement.

Reliability improved: Production delays decreased by 85%, with problems identified before becoming crises.

Customers noticed: On-time deliveries jumped from 73% to 94%.

The biggest change wasn’t measurable. Ahmad’s team focused on creating products rather than fighting systems. A board member asked: “Beyond efficiency, does this system actually make our people less stressed and more effective?” The answer was yes. Teams spent less time firefighting and more time innovating. During the project review, BiztechCS asked the COO: “What does a 20% efficiency improvement mean for expansion plans?” His answer accelerated the opening of their second facility by six months.

What if your factory could cut material costs by 15% while boosting efficiency at the same time?

Success came from focusing on gradual, people-centered change instead of overwhelming transformation.

The BiztechCS Difference

Most odoo erp software development projects fail because they attempt to change everything at once. People get overwhelmed, resistance builds, and expensive software sits unused.

BiztechCS takes a different approach—optimizing manufacturing operations with Odoo by supporting good people with better tools.

Our method:

The manufacturer succeeded because BiztechCS treated this as an operational improvement using technology, rather than just a technology project aimed at improving operations.

This leading manufacturer demonstrates that transformation is not only possible, but also practical and profitable. Methodical optimization of manufacturing operations with Odoo delivers significant improvements without disrupting operations.

Successful manufacturing transformations view ERP as operational excellence initiatives powered by technology, rather than just technology projects aimed at improving operations. This principle guides every BiztechCS engagement.

Consider these questions:

Manufacturing excellence doesn’t require the newest equipment or the biggest facilities—it requires systems working together smoothly, clear visibility, and smart decision-making at every level.

Whether managing a single facility or multiple sites, the fundamentals stay consistent: connect processes, automate routine tasks, and give teams actionable, real-time information.

Ready to optimize manufacturing operations with Odoo? Whether for a single factory or a global network, BiztechCS designs solutions that scale with production needs.

Artificial Intelligence (AI)

366

By Nandeep Barochiya

Odoo

435

By Uttam Jain

Artificial Intelligence (AI)

764

By Nandeep Barochiya