UAE Manufacturing Success: From System Breakdown to Operational Excellence with Odoo

5 min read

5 min read

Ahmed Khalil dreaded Monday mornings. As the Operations Manager at a growing UAE industrial fabrication company, he watched the same disasters unfold every week. Equipment would break down without warning. Production would stop. Emergency repairs ate into budgets.

His company was growing fast. New contracts kept coming in. They were planning a second fabrication plant. But their systems couldn’t keep up.

Production schedules had lived in Excel files. Three different people updated them simultaneously. Chaos was inevitable. Maintenance records were filed in old filing cabinets. Finding equipment history took hours. The procurement team spent their days putting out fires instead of planning.

The numbers told the story. According to a study, 72% of manufacturers still use manual processes for critical operations. This resulted in annual delays of 15-20%.

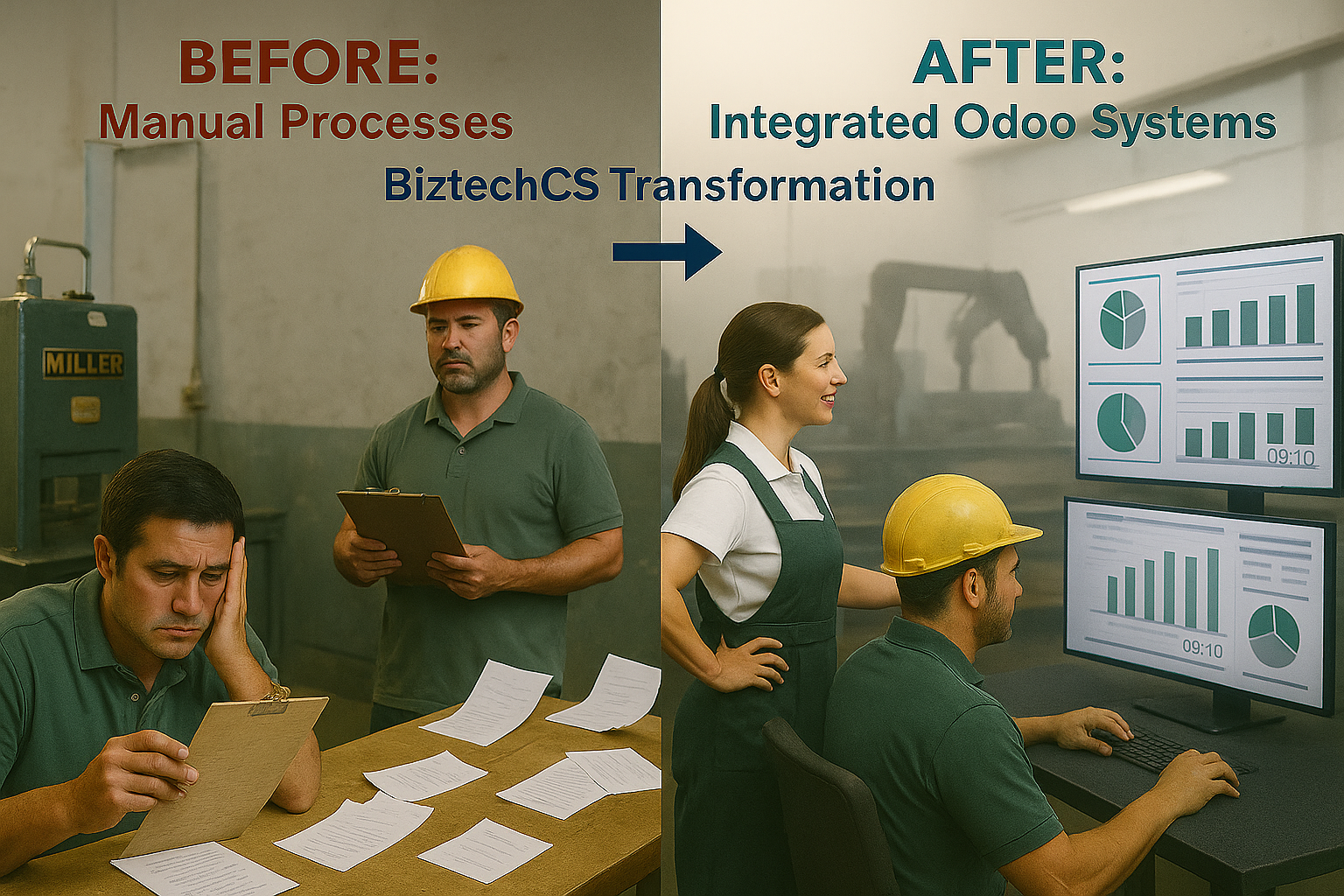

However, once BiztechCS stepped in, everything changed. We implemented an integrated system that streamlined production scheduling, maintenance tracking, and procurement operations. The days of chaotic spreadsheets and manual tracking were over.

With real-time data accessible at their fingertips, the operations team could plan, minimizing downtime and increasing efficiency. The procurement team was now empowered to focus on strategic tasks rather than dealing with emergencies.

BiztechCS had configured a tailored solution that improved operational reliability, reduced delays, and positioned the company to scale up smoothly for its second plant. What was once a company struggling to keep up was now a model of operational excellence.

The crisis hit on a Monday morning in March. Their main milling machine failed during the night shift. The breakdown stopped production on their biggest contract of the year.

The maintenance team rushed to diagnose the problem. They needed specific replacement parts. The team scrambled to find suppliers. The parts would take five days to arrive.

A two-hour repair turned into a week of downtime. The client was furious. The team was exhausted. Ahmed realized their manual systems were killing their growth.

“We spent every day reacting to problems,” Ahmed told us later. “We never had time to prevent them.”

When we first met Ahmed, we asked him a simple question that many manufacturers struggle with: “Can your team predict equipment failures before they stop production?” His honest answer was no.

This is exactly why BiztechCS had stepped in to transform their operations. We had conducted a thorough assessment and identified critical gaps in the company’s processes. Instead of rushing to automate the existing broken systems, BiztechCS delivered a tailored solution that focused on fixing those processes first. BiztechCS implemented the best Odoo ERP development for Manufacturing and Maintenance, enabling real-time visibility, predictive maintenance, and cross-departmental coordination.

By switching from a reactive approach to a proactive one, BiztechCS helped the company avoid costly downtime and plan. The days of scrambling for suppliers and reacting to breakdowns were over. The systems are now equipped to predict issues before they could disrupt production.

Our team visited the facility in April. Instead of diving straight into software features, we observed how the team operated. We attended their morning production meetings. We shadowed maintenance technicians as they made their rounds. We sat with staff during their daily scrambles.

These observations revealed the real problem. The company didn’t need new systems everywhere—they needed their existing processes to communicate effectively. They required Odoo MRP for manufacturing optimization, which would connect production, maintenance, and procurement.

BiztechCS identified three critical gaps that were costing the company money every day. Production schedules had no link to inventory levels. Maintenance activities were disconnected from production plans. Staff waited until materials ran out before placing orders.

During our initial consultation, we explored a crucial question with Ahmed’s team: “Is your current system giving you the visibility to make smart decisions about production and resources?” The frustration with the answer led BiztechCS to design a solution that completely transformed their operations.

BiztechCS began its Odoo ERP implementation journey for the MRP System in Production Planning back in May. This wasn’t about simply replacing spreadsheets with fancy software. The goal was to create a living production system—one that could adapt to real-time changes and evolving demands.

The new MRP module provided production planners with instant access to critical information. They could see material availability in real-time, check equipment capacity immediately, and track order status without making phone calls.

However, BiztechCS first had to clean up its data. Item codes were inconsistent. Bills of materials had errors. Routing information was incomplete. BiztechCS spent two weeks getting the foundation right. As we often advise our clients, Odoo Inventory Management for Manufacturing functions effectively only with clean data—the time spent on proper setup pays off quickly in terms of accuracy.

When we asked the production team how fast they could currently get accurate information about materials and capacity, the answer was hours or sometimes days. BiztechCS changed that for the better.

The results were evident quickly. Production delays dropped from 25% to under 10% in the first month. More importantly, the stress levels in the production office went down. People could plan instead of panic.

With production running smoothly, BiztechCS turned its focus to maintenance in June. The goal was to implement Odoo Maintenance Management for Industrial Fabrication, which would prevent problems rather than fix them after they occurred.

BiztechCS connected equipment data to production schedules. Machine hours, maintenance history, and performance trends were consolidated into a single dashboard. The system could predict when equipment needed attention.

Fatima Al-Rashid, who runs the maintenance team, explained the change: “The system tells us when machines need work based on actual usage. We schedule maintenance during planned downtime. No more emergency shutdowns.”

During the implementation of the maintenance module, BiztechCS discussed an essential question with Fatima’s team: “Do your maintenance schedules use actual equipment data or just calendar dates?” Most teams were using outdated calendar-based approaches. BiztechCS changed this completely. The Odoo Preventive Maintenance System now operates optimally when integrated with production planning. BiztechCS helped the company schedule maintenance to prevent disruptions to critical orders.

The results were impressive. Unplanned downtime dropped by 40% in three months. Maintenance costs fell by 25%. Equipment ran more reliably. Product quality improved.

Ready to see how integrated systems could eliminate your production headaches? BiztechCS delivered a solution that solved these exact challenges. We can help you design a system tailored to your specific manufacturing needs.

The final piece was Odoo Procurement Automation for Manufacturing in July. BiztechCS, a leading Odoo ERP development company, connected procurement triggers to production plans and inventory levels. The system could anticipate material needs weeks in advance, ensuring smoother workflows, minimized downtime, and cost efficiency across operations.

No more crisis ordering. No more expensive rush deliveries. Purchase orders were generated automatically based on production schedules and supplier lead times. The procurement team could focus on identifying more effective suppliers and negotiating more favorable prices.

While working with the procurement team, BiztechCS examined the allocation of time between emergency orders and strategic sourcing. The answer was shocking: 80% emergency, 20% strategic. BiztechCS knew that procurement automation needed accurate supplier data. The team spent time cleaning up vendor information before going live because they understood that accuracy drives results.

The procurement transformation eliminated the constant material crises. Production could now rely on having what they needed when they needed it.

By the end of two months, the numbers told the story of transformation:

Production Improvements

Maintenance Success

Procurement Wins

The culture shifted, too. Teams moved from fighting fires to preventing them. People were happier at work. Clients were more satisfied. Profits improved.

Ahmed summed it up like this: “Our people are engaged. Our clients are happy. Our operations are profitable. BiztechCS didn’t just change our software—they changed how we think about manufacturing.”

If BiztechCS were to implement an Odoo ERP solution for Manufacturing and Maintenance, the success would come from three key decisions made during the process:

We rolled out one module at a time. Each team mastered new tools before adding more complexity—success built on success.

Fix First, Automate Second

We focused on improving processes before automating them. Bad processes can become bad automated processes, while good processes can become great with the aid of automation.

People-Centered Change

We invested heavily in training and support. It wasn’t just about showing teams how to use the new system, but explaining why the changes would make their jobs easier and more effective.

During the change management process, BiztechCS consistently explored how companies typically handle large system changes and what approaches worked best in getting people on board.

We understood that even the most sophisticated Odoo MRP for Manufacturing Optimization system would fail if the people using it didn’t embrace it. Training and support were treated as investments in success, not an expense.

Every manufacturing company faces different challenges. Your situation won’t look precisely like Ahmed’s fabrication facility. However, the basic principles that BiztechCS applies remain the same. You need integrated systems. You need proactive processes. You need change management that puts people first.

Perhaps you’re experiencing production delays. Maybe maintenance costs are eating your profits. Maybe inventory management is a constant headache. Maybe you need better visibility into operations.

BiztechCS understands manufacturing operations because its team works in them every day. They sit in production meetings. They walk factory floors. They are familiar with the pressure of tight deadlines and demanding clients.

Manufacturing excellence doesn’t happen overnight. It grows through careful improvements, smart planning, and solutions built for your specific needs. The question isn’t whether you need better systems. The question is when you’ll start building them with BiztechCS.

BiztechCS can help you explore what operational excellence could look like in your facility. They start by understanding your unique challenges and goals. Every transformation begins with an honest conversation about where you are and where you want to go.

Want to discover how BiztechCS can revolutionize your manufacturing operations like they did for Ahmed’s company? Let’s schedule a consultation to discuss your specific challenges and design a solution that delivers real results.

Odoo

145

By Uttam Jain

Artificial Intelligence (AI)

284

By Nandeep Barochiya

Odoo

144

By Uttam Jain