High-Precision Production Management Powered by Odoo

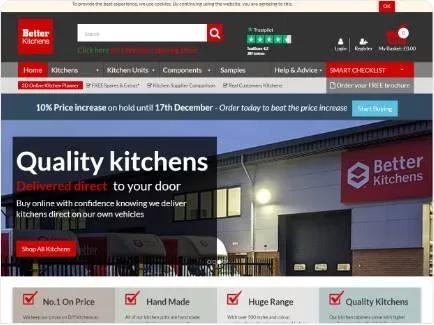

Fragmented spreadsheets and disconnected workshop data often create massive blind spots for leadership, leading to costly inventory discrepancies and missed delivery deadlines. BiztechCS addresses these operational hurdles by implementing a centralized digital hub that bridges the gap between custom client specifications and physical stock availability.

By integrating an Odoo ERP for kitchen manufacturers, we replace traditional manual tracking with automated replenishment rules for hardware, timber, and stone. Our specialized manufacturing tools improve machine uptime and shorten the assembly phase, boosting overall shop-floor output.

Consolidating retail sales and factory logistics into a single dashboard provides your executive team with full transparency across the entire project lifecycle. This holistic approach removes the administrative burden of cross-referencing multiple design, accounting, and procurement software systems.

Your purchasing department can finally evaluate supplier reliability based on hard performance data rather than intuition. Adopting a tailored Odoo ERP for kitchen businesses establishes a resilient foundation that maintains steady production even during sudden industry fluctuations.

This transition converts your production line into a flexible, predictable engine for sustained financial growth.

Optimizing Your Enterprise with Our Comprehensive Odoo Kitchen Services

Our full-scale Odoo ERP services for the kitchen industry are built to harmonize workshop tasks and modernize aging workflows. Designed around real production environments, Odoo ERP for kitchen manufacturers delivers end-to-end visibility across the entire project lifecycle. It preserves the craftsmanship and proven processes that define your brand.

Optimizing Your Enterprise with Our Comprehensive Odoo Kitchen Services

Bespoke Odoo Kitchen System Deployment

Secure Technical Migration

Manufacturing Equipment & CAD Connectivity

Kitchen Sector Strategy & Digital Consulting

Production Planning & Capacity Optimization

Inventory Intelligence & Material Traceability

Quality Control & Process Standardization

Post-Implementation Support & System Evolution

Address Your Primary Production Hurdles with Odoo ERP for Kitchen

Do you have specific concerns regarding the digitization of your cabinet shop or the integration of your showroom data? Share your operational goals with us, and our specialists will provide a detailed transition plan and a technical setup designed for your specific business.

Advantages of Our Odoo ERP for Kitchen Management

Our Odoo-based kitchen solutions provide tangible gains in efficiency, financial oversight, and manufacturing stability. Every feature is designed to strengthen control and help you make data-driven decisions as your company grows.

Substantial Savings in Workshop Costs

We eliminate redundant clerical work and costly measurement errors that quietly erode daily profits. By automating work-order generation and material planning in Odoo, your team can handle a higher project volume without adding overhead. This operational efficiency directly translates into stronger margins, especially for manufacturers adopting Odoo ERP in kitchen production environments.

Flexible Framework & Information Accuracy

Our implementations resolve the data conflicts common in legacy systems, creating a single, reliable source of truth across your operations. As your brand expands with new galleries or additional fabrication lines, the platform scales smoothly without performance loss. This consistency gives technical leadership a dependable foundation for sustainable, long-term growth.

Swift Planning via Real-Time Analytics

We exchange delayed weekly reports for live data visualizations of material yields and labor costs. Instant access to verified metrics allows the board to pivot based on current factory capacity rather than outdated summaries. CFOs gain the insight needed to protect margins amid rising raw material prices.

End-to-End Component Tracking

Our platform offers complete visibility across the fabrication journey—from the arrival of raw boards to the final home installation. Automated serial numbering ensures adherence to safety standards and simplifies quality audits. This transparency makes managing warranties easier and boosts your reputation for quality.

Words that make an impact

Success Stories of Digital Transformation Developed By BiztechCS

Our persistence and enthusiasm to work with technologies have helped us go above and beyond our client’s expectations. Here, explore many of our successful projects which digitally transformed businesses.

Tech Updates from Team BiztechCS

At BiztechCS, we keep you at the edge of technology with the latest updates, news, and trends influencing the IT industry. Our blog has a unique approach and is well-researched to give you a fresh perspective on technology.

The Future of Odoo Development: Trends Every Business Should Watch

Introduction Odoo has quickly become one of the most comprehensive open-source ERP systems that revolutionized business management with its modularity and intuitive interface. Looking...

Which Tools and Extensions Can Boost Your Odoo Development Efficiency?

Introduction Most developers who are working with Odoo are always searching for tools and modules that could help them save time and be more efficient. Such tools may assist in code...

Complete Guide to Odoo Development: Pro Techniques for Scalable Business Applications

Introduction Odoo development offers a unique way to create custom solutions for businesses. Mastering this platform can significantly enhance your project’s efficiency. To succeed,...Why Partner With BiztechCS for Your Odoo ERP for Kitchen Solutions?

Picking the right implementation team is just as vital as the software. Our method merges deep coding skills with an understanding of kitchen manufacturing to ensure lasting success.

- Deep Domain Knowledge in Cabinetry & Woodworking

- Accredited Odoo Functional Architects

- Global Support Desk Available Round the Clock

- Custom-Engineered Production Workflows

- Rigorous Standards for Project Data Transfer

- Seamless Integration with Design & CNC Tools

- Heavy Emphasis on Intellectual Property Security

- ROI-Focused Implementation Logic

- Choice of Private Cloud or Local Server Setup

- Thorough User Guides & Hands-on Training

Grow Your Kitchen Brand with Professional Odoo Setup

We partner with your team from the initial shop-floor audit to translate your specific assembly steps into Odoo. This thorough review ensures we fix the exact friction points in your design and fabrication cycles before we begin the technical configuration. The result is a solution tailored to your production realities, including Odoo ERP for kitchen manufacturing environments.

Work closely with our lead consultants from the strategy phase through to go-live. Together, we build a transparent, high-output production environment that improves visibility, efficiency, and operational control across your shop floor.

Frequently Asked Questions

How does the system manage custom cabinet sizes and material variations?

Our Odoo setups use a flexible configuration engine that handles an infinite number of size and finish combinations. When a salesperson enters specific kitchen dimensions, the system instantly recalculates the required panels, edging, and hardware, creating a precise Bill of Materials for the workshop.

Can Odoo connect with our existing design software and workshop tools?

Definitely. We use the Odoo IoT framework to connect your ERP directly to CNC routers and specialized kitchen design programs. This allows technical files to move automatically to production, eliminating the need for manual re-entry and preventing human error on the factory floor.

What is the typical timeframe to see a return on an Odoo kitchen project?

Most of our clients realize their investment within the first year by reducing material scrap and shortening the time from deposit to installation. Financial gains are often driven by better cash flow management and the ability to fulfill more orders with the same workshop footprint.

Is Odoo robust enough to handle a network of showrooms and a central factory?

Yes, Odoo is built for multi-site operations. It allows each showroom to function as its own entity while centralizing production at your main facility. You can track real-time stock levels across all locations and manage inter-branch logistics from a single login.